Nothing is rubbish when digital tech meets the circular economy

Guest Writer

- Published

- Opinion & Analysis

Waste-to-energy is a linchpin of the circular economy. With predictive data tools and artificial intelligence, the sector is getting a radical reboot, writes Sue Quense, Chief Commercial Officer, AVEVA

What if every orange peel you threw away could power your coffee machine the next morning? That peel is waste but it’s also a missed opportunity to capture badly needed energy and reduce greenhouse gas emissions.

As it decomposes, organic waste like fruit peels produces methane, one of the major gases responsible for global warming. Since the industrial revolution, methane has accounted for a third of worldwide temperature increases according to IEA’s Global Methane Tracker 2024. But when captured at source, this methane can be repurposed into low-carbon renewable natural gas (RNG). Like conventional natural gas, RNG can be used for heating, cooking and transport. More methane captured from waste means more gas for life’s needs – like your morning coffee.

Why should the issue stimulate us now? Simply because the world is generating more trash than ever before. Every minute, 3,825 tons of municipal waste is produced and collected. Or about 2.01 billion tons of municipal solid waste per year, with at least a third being managed in a way that isn’t environmentally friendly, according to the World Bank. That’s going to grow to 3.40 billion tons by 2050.

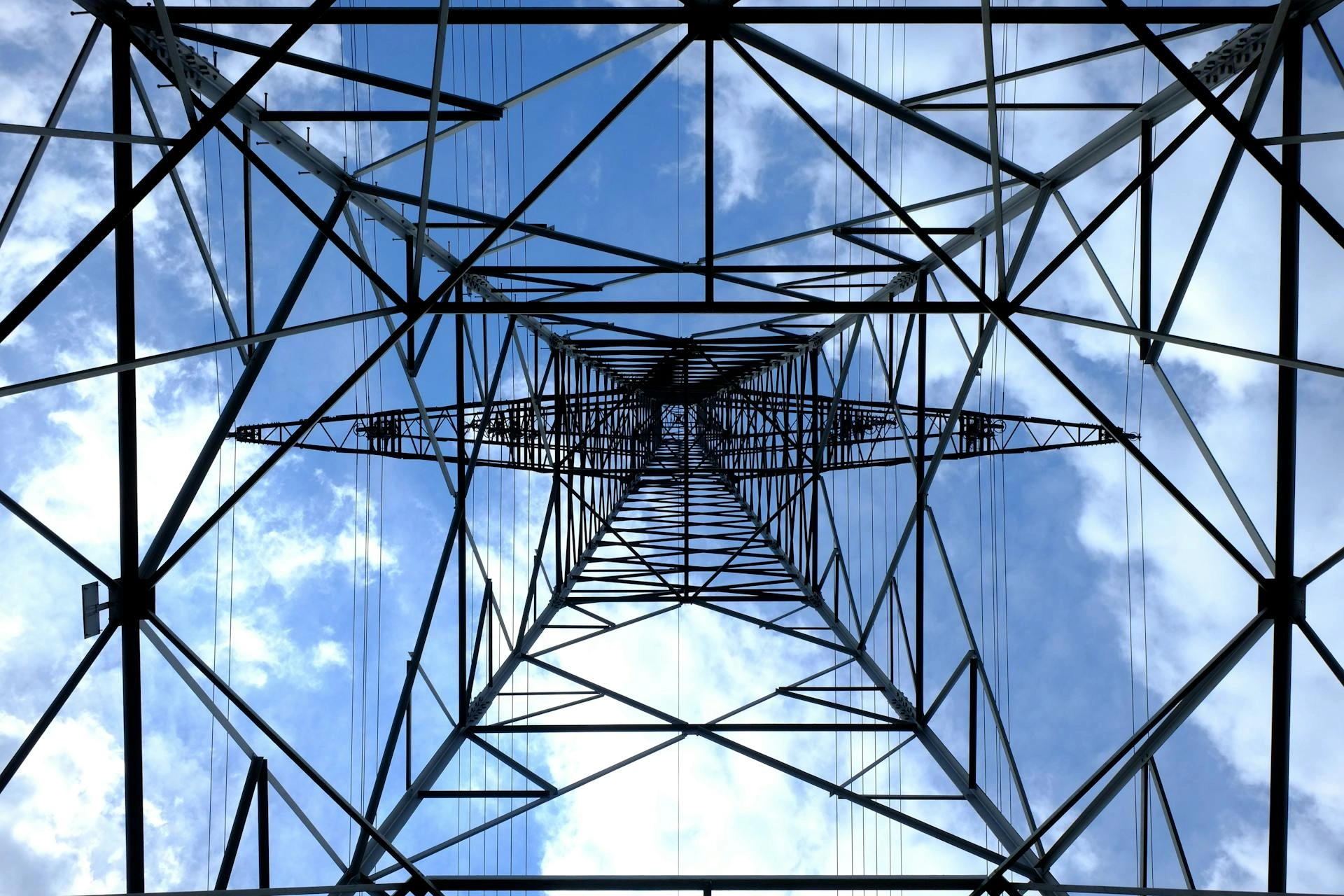

The world has a waste problem. At the same time, global energy demand is growing, fueled by economic growth and a rising population: by 2050, global electricity use is likely to increase by one-third to three quarters, according to the US Energy Information Administration. Organic waste can help tackle both problems – with help from Fourth Industrial Revolution (4IR) technologies. Internet of things sensors, data analytics and artificial intelligence (AI) are now rewriting the rules of resource recovery and biogas production.

Turning trash into energy with digital technologies

As nations tighten circular‑economy mandates and climate targets, digital tools are transforming waste streams into reliable energy sources. Cloud-connected data platforms and AI analytics enable waste-to-energy teams to monitor every step of the value chain, from feedstock input to energy output, all in real time. This improves plant uptime, anticipates maintenance and optimises throughput – while helping meet environmental compliance targets.

Tracking the journey of materials and energy makes circular, sustainable energy a practical reality. This is the circular economy in action: turning yesterday’s trash into tomorrow’s power. Maintaining our current consumption levels would require the resources of 2.3 planets by 2050, according to the World Business Council for Sustainable Development. By shifting to a circular economy – where we reduce, reuse and recycle – consumers can decouple global growth from consumption, the World Economic Forum says. It describes the circular economy as the business opportunity of our time. Digital tools are essential to building and scaling circular value chains and can deliver transformative change as part of a comprehensive approach that includes policy measures and lower resource use.

Regulating the loop to catalyse innovation

That’s why circular infrastructure sectors such as waste-to-energy are now a policy priority for many countries. As industrial waste streams evolve in volume and complexity, policymakers are beginning to realise the value of circular economic approaches.

For example, the EU’s new Green Deal and its circular economy action plan aim to make sustainable product the norm – through regulatory measures, financial instruments and information-based tools aimed at steering businesses towards circular practices. The bloc’s Waste Framework Directive promotes waste prevention, reuse and recycling alongside energy recovery. The EU’s waste-to-energy plants will also soon need to report on and pay for greenhouse gas emissions.

Equipment upgrades – new boilers, for example – may reduce emissions at source, but that won’t deliver the efficiency gains or emissions visibility required. Waste-to-energy operators are facing increasing pressure to capture, analyse, and report data in real time with greater transparency and accuracy. Digital technologies make it possible to turn compliance into a strategic advantage. True efficiency comes from using AI and real-time data analytics at every level: to monitor emissions, reduce resource time, and predict equipment uptime.

For existing plants, that means deploying cloud-based traceability platforms that support transparent, accurate reporting – so we can quantify the emissions avoided when food waste like peels is digested for energy. We also need a new generation of RNG plants built with modular design principles, integrated sensors and cloud-ready architectures. We need smarter plants constructed to adapt to changing feedstocks and environmental standards.

Closing the loop from design to optimisation

Better design, optimising business models and improving our circular infrastructure are the most promising areas of circular economy innovation, according to the Ellen MacArthur Foundation, the worldwide circularity leader.

Companies are already putting these principles into action. To enhance business outcomes, waste-to-energy facilities are becoming data‑driven hubs, where sensors capture temperature, pressure and gas‑composition data at every stage of combustion; cloud platforms centralise this information for cross‑site visibility; and AI algorithms translate this data into actionable insights to support better decisions, from predictive maintenance to throughput optimisation.

In the UK, circular economy leader Suez keeps energy-from-waste plants up and running thanks to AI-generated early warnings, preventing days of costly downtime, saving costs and most importantly, keeping GHG emissions in check. Unplanned downtime erodes the waste-to-energy sector’s ability to compete with other energy alternatives.

BP’s Archaea Energy takes it one step further: By pulling end-to-end lifecycle data from different plants into one single-window interface, teams can visualise real-time performance for optimal efficiency and to make the most of operational opportunities. They can make smarter decisions and do more with less, transforming operational complexity into a competitive advantage and achieving higher ROI.

Beyond virtualisation, Archaea is also using 4IR technologies to scale up its portfolio. Its new plants are built off a modular design using skid‑mounted units to streamline installation and reduce site civil works. When coupled with cloud‑based configuration management and digital twin testing, each module can be commissioned in weeks rather than months. The company sees bioenergy delivering around $2 billion EBITDA in 2025 and aiming to deliver more than $4 billion in 2030.

Powering the circular economy with data

From an orange peel to a kilowatt of clean energy, the digital evolution of organic waste shows what’s possible when advanced technologies meet circular‑economy principles. IoT sensors make decomposition visible, analytics optimise production and AI drives predictive operations.

As policy frameworks tighten and market incentives align with sustainability goals, it will be more important than ever for waste-to-energy operators to harmonise data standards across their value chains and scale digital approaches. Only then will we be truly able to fulfill the circular economy’s promise of turning every scrap of waste into a resource for a sustainable future.

Main image: Supplied

RECENT ARTICLES

-

Europe cannot call itself ‘equal’ while disabled citizens are still fighting for access

Europe cannot call itself ‘equal’ while disabled citizens are still fighting for access -

Is Europe regulating the future or forgetting to build it? The hidden flaw in digital sovereignty

Is Europe regulating the future or forgetting to build it? The hidden flaw in digital sovereignty -

The era of easy markets is ending — here are the risks investors can no longer ignore

The era of easy markets is ending — here are the risks investors can no longer ignore -

Is testosterone the new performance hack for executives?

Is testosterone the new performance hack for executives? -

Can we regulate reality? AI, sovereignty and the battle over what counts as real

Can we regulate reality? AI, sovereignty and the battle over what counts as real -

NATO gears up for conflict as transatlantic strains grow

NATO gears up for conflict as transatlantic strains grow -

Facial recognition is leaving the US border — and we should be concerned

Facial recognition is leaving the US border — and we should be concerned -

Wheelchair design is stuck in the past — and disabled people are paying the price

Wheelchair design is stuck in the past — and disabled people are paying the price -

Why Europe still needs America

Why Europe still needs America -

Why Europe’s finance apps must start borrowing from each other’s playbooks

Why Europe’s finance apps must start borrowing from each other’s playbooks -

Why universities must set clear rules for AI use before trust in academia erodes

Why universities must set clear rules for AI use before trust in academia erodes -

The lucky leader: six lessons on why fortune favours some and fails others

The lucky leader: six lessons on why fortune favours some and fails others -

Reckon AI has cracked thinking? Think again

Reckon AI has cracked thinking? Think again -

The new 10 year National Cancer Plan: fewer measures, more heart?

The new 10 year National Cancer Plan: fewer measures, more heart? -

The Reese Witherspoon effect: how celebrity book clubs are rewriting the rules of publishing

The Reese Witherspoon effect: how celebrity book clubs are rewriting the rules of publishing -

The legality of tax planning in an age of moral outrage

The legality of tax planning in an age of moral outrage -

The limits of good intentions in public policy

The limits of good intentions in public policy -

Are favouritism and fear holding back Germany’s rearmament?

Are favouritism and fear holding back Germany’s rearmament? -

What bestseller lists really tell us — and why they shouldn’t be the only measure of a book’s worth

What bestseller lists really tell us — and why they shouldn’t be the only measure of a book’s worth -

Why mere survival is no longer enough for children with brain tumours

Why mere survival is no longer enough for children with brain tumours -

What Germany’s Energiewende teaches Europe about power, risk and reality

What Germany’s Energiewende teaches Europe about power, risk and reality -

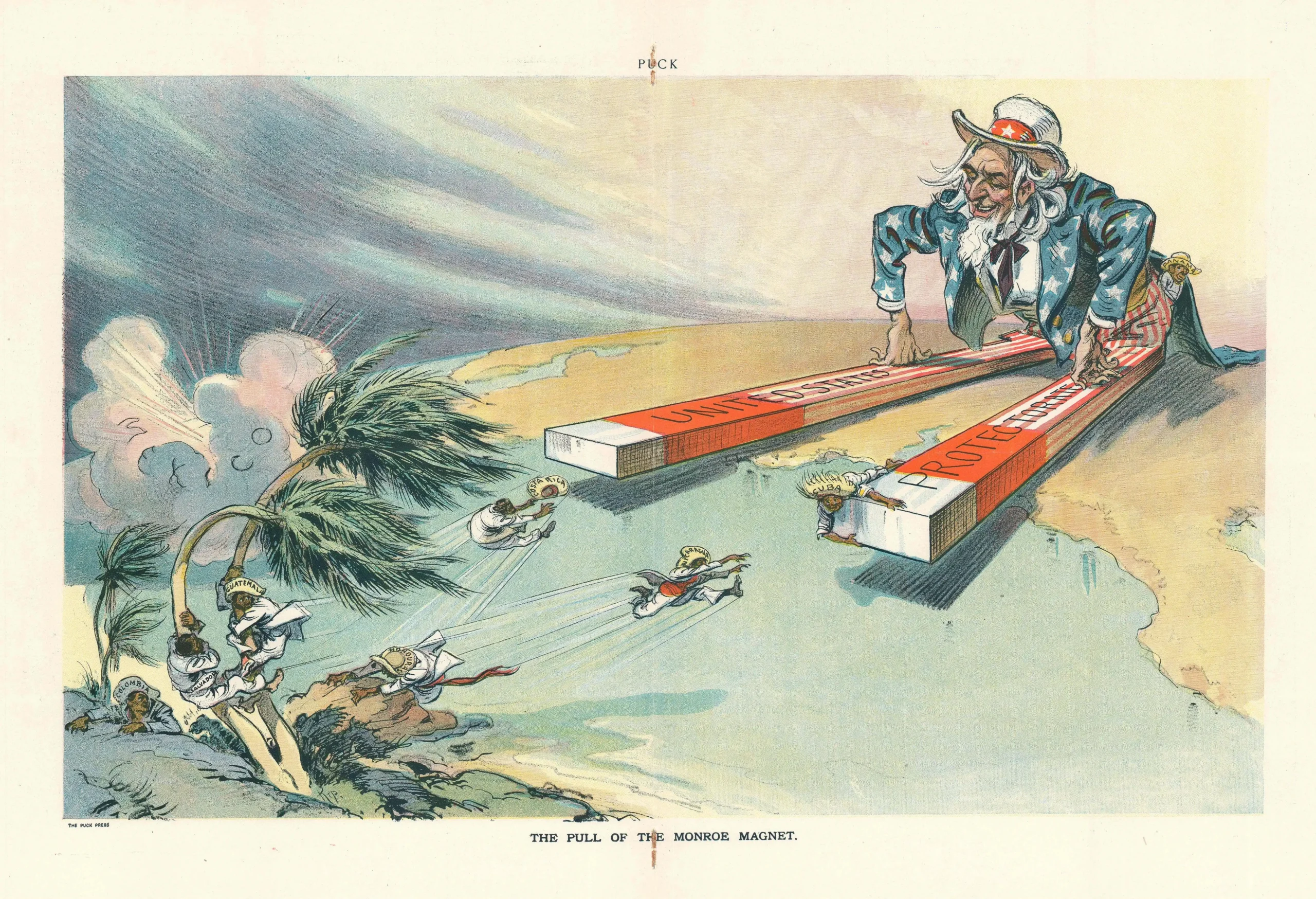

What the Monroe Doctrine actually said — and why Trump is invoking it now

What the Monroe Doctrine actually said — and why Trump is invoking it now -

Love with responsibility: rethinking supply chains this Valentine’s Day

Love with responsibility: rethinking supply chains this Valentine’s Day -

Why the India–EU trade deal matters far beyond diplomacy

Why the India–EU trade deal matters far beyond diplomacy -

Why the countryside is far safer than we think - and why apex predators belong in it

Why the countryside is far safer than we think - and why apex predators belong in it