A major breakthrough to a massive problem

John E. Kaye

- Published

- Home, Sustainability

Plastic Energy has pioneered a brand new technology to help boost the lifecycle of plastics – one that many major companies are now investing in

Plastic waste has been increasing exponentially for the past few decades and is expected to grow another 70% by 2030. And from plastic waste comes plastic pollution, which is reaching crisis point. Currently, only 14% of plastics are collected for recycling, and around 40% are sent to landfill, 14% are incinerated, and 32% leak into the environment.

Global chemical recycling leader Plastic Energy has a solution to recycle more plastics and reduce plastic waste. Their unique and patented technology uses a thermal anaerobic conversion (TAC) process to treat end-of-life-plastics that cannot be mechanically recycled. Through this process, a recycled oil (called TACOIL) is produced. This TACOIL is then used to replace fossil oils in the manufacturing of virgin-quality plastics that can be used for food-grade packaging.

Chemical recycling – also called advanced recycling – is complementary to mechanical recycling and is not designed to compete with or replace it, but rather overcome some of its limitations. Plastic Energy’s process can recycle plastics that are unable or difficult to be mechanically recycled (such as plastic films or flexibles), and would otherwise end up in landfills, incinerators, or leaking into the environment. With mechanical recycling, many plastics, except for polyethylene terephthalate (PET) bottles, are downcycled and cannot be used for food-grade applications. Plastic Energy’s TACOIL has the same properties as virgin fossil oil and meets all the safety standards and requirements to be used for the manufacturing of food-grade packaging.

Certified as sustainable

Plastic Energy currently has two commercial chemical recycling plants in Almeria and Seville, Spain, which have been in operation for the last six years. Since 2019, both plants have been certified through ISCC PLUS, a sustainability certification system following the mass-balance approach. In December 2020, Plastic Energy’s Seville plant became the first end-of-life plastics chemical recycling plant to achieve the Roundtable on Sustainable Biomaterial (RSB) certification.

Food-grade packaging with recycled content from Plastic Energy’s TACOIL has already been commercialised in Europe. In 2020, Unilever’s Magnum and Knorr pots made with recycled content were released on to the European market. Tupperware’s Eco+ Straw Set and Vinventions Blue Line wine closures have also been manufactured with recycled content from TACOIL, and Mondelez will incorporate this recycled content into their Philadelphia cream cheese packaging, starting this year.

Plastic Energy are continuing to increase their portfolio of European projects with a 20,000 tonne per annum capacity recycling plant that is currently under construction in the Netherlands with partner, SABIC. Also, a 25,000 tonne plant has just begun construction in France, along with a collaboration offtake agreement with ExxonMobil. They also have another 15,000 tonne capacity recycling plant with partner TotalEnergies at their Grandpuits site in France, which is due to be built soon.

Plastic Energy has also signed a collaboration agreement with Nestlé, exploring the potential for a chemical recycling project in the UK, and an MoU with Petronas for a recycling plant in Malaysia. In the US, Plastic Energy has partnered with Freepoint Eco-Systems for a new 33,000 tonne recycling plant in Texas and signed an offtake collaboration agreement with TotalEnergies.

In November 2021, Plastic Energy announced the completion of a significant capital raise of $166m from three separate investors: LetterOne, Axens and M&G. These funds will be used to accelerate Plastic Energy’s growth and enable it to expand its technology and global portfolio of recycling plants. In addition, Plastic Energy also signed a collaboration with Axens to license their technology to customers.

“This fundraise and our new investors will have a big impact and will set our company up for success in the future,” said Carlos Monreal, Founder and CEO of Plastic Energy. “It is encouraging to have the support of these global companies who share our vision in reducing plastic waste and have confidence in our patented and proven chemical recycling technology.”

CEO of Plastic Energy

Plastic Energy has become increasingly invested in becoming more sustainable and has embedded sustainability into its core values. They are a signatory for the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment and have pledged to convert at least 300,000 tonnes of end-of-life plastic waste into feedstock for new plastic manufacturing by 2025. As of April 2020, all Plastic Energy’s TACOIL has been used to create new plastics, which benefits the circular economy. From an independent lifecycle analysis (LCA) that was conducted by sustainability consultants in 2020, Plastic Energy’s chemical recycling process was found to have a considerably lower climate change impact than incineration with energy recovery. In addition, plastics made from Plastic Energy’s recycling process have a lower climate change impact than virgin plastic. Plastic Energy released its inaugural sustainability report in August 2021. This report outlined a variety of sustainability goals, including a pledge to reach net-zero emissions by 2050.

Plastic Energy is focused on redefining the plastic landscape and reducing the climate impact of plastic. By working with the entire plastics value-chain, the company is paving the way for making plastics more sustainable.

For further information:

plasticenergy.com

Our video interview with Carlos Monreal is available to view here

Sign up to The European Newsletter

RECENT ARTICLES

-

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests -

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement -

Historic motorsport confronts its energy future

Historic motorsport confronts its energy future -

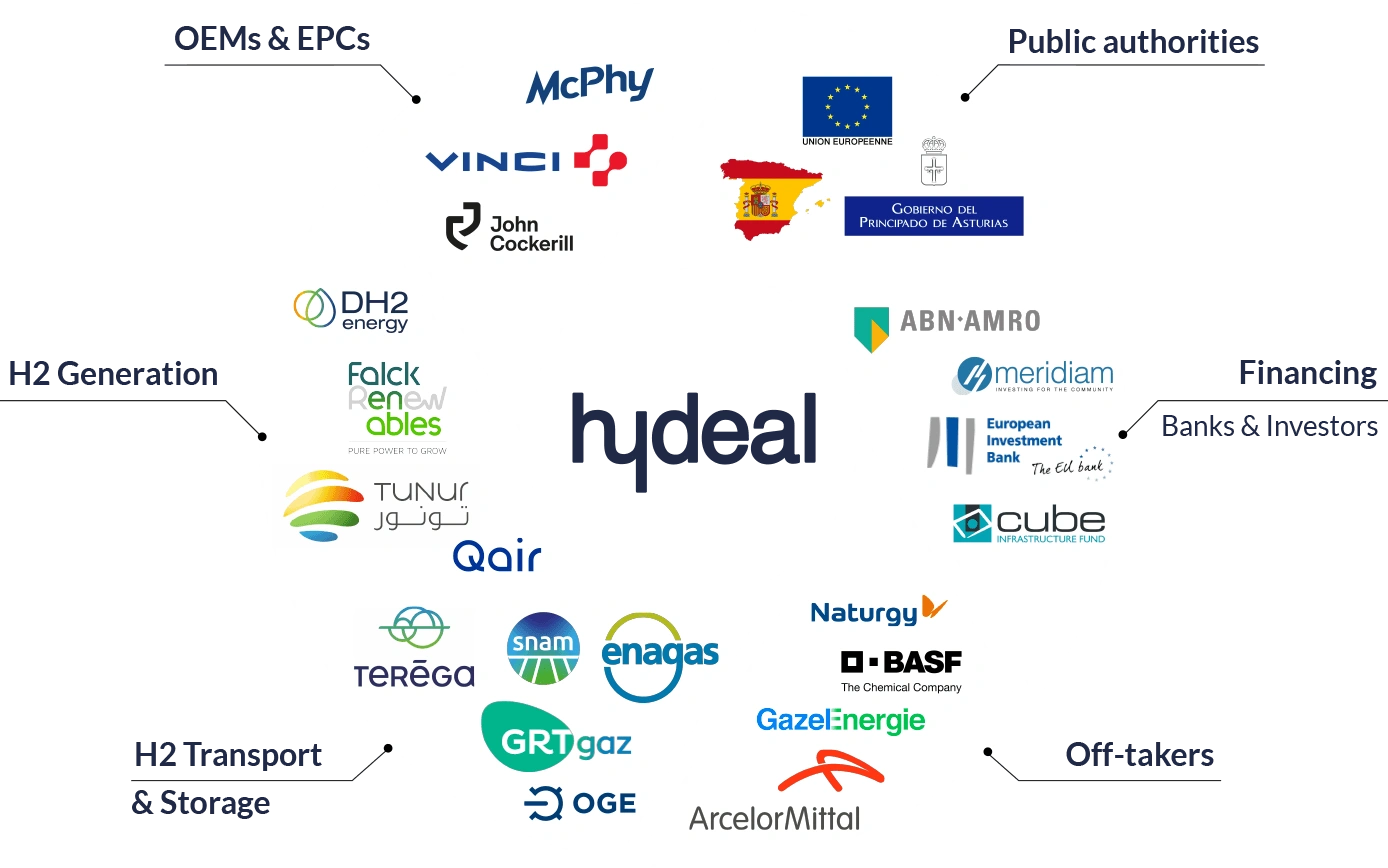

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe -

Fabric of change

Fabric of change -

Courage in an uncertain world: how fashion builds resilience now

Courage in an uncertain world: how fashion builds resilience now -

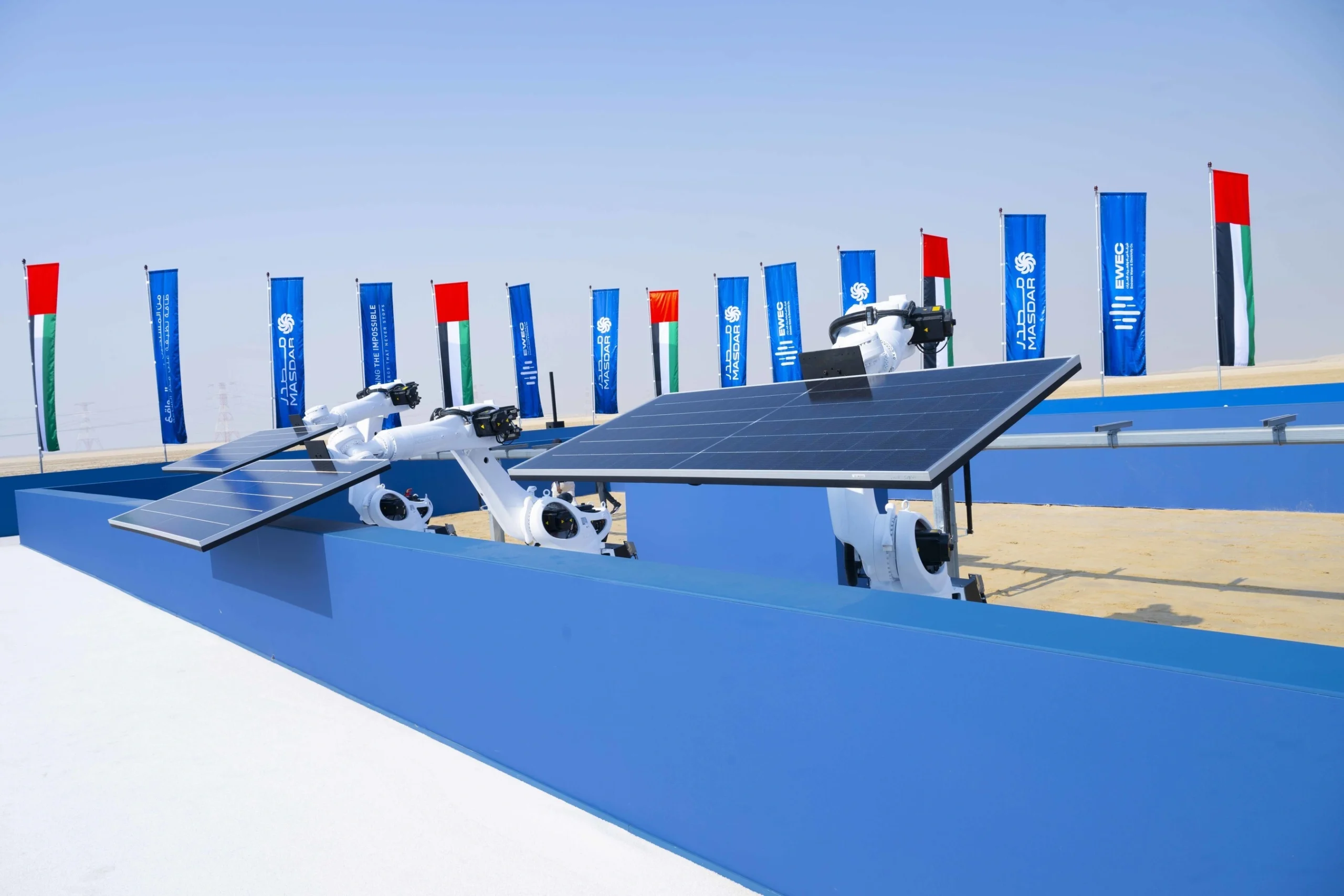

UAE breaks ground on world’s first 24-hour renewable power plant

UAE breaks ground on world’s first 24-hour renewable power plant -

Inside Iceland’s green biotechnology revolution

Inside Iceland’s green biotechnology revolution -

Global development banks agree new priorities on finance, water security and private capital ahead of COP30

Global development banks agree new priorities on finance, water security and private capital ahead of COP30 -

UK organisations show rising net zero ambition despite financial pressures, new survey finds

UK organisations show rising net zero ambition despite financial pressures, new survey finds -

Gulf ESG efforts fail to link profit with sustainability, study shows

Gulf ESG efforts fail to link profit with sustainability, study shows -

Redress and UN network call for fashion industry to meet sustainability goals

Redress and UN network call for fashion industry to meet sustainability goals -

World Coastal Forum leaders warn of accelerating global ecosystem collapse

World Coastal Forum leaders warn of accelerating global ecosystem collapse -

Miliband: 'Great British Energy will be self-financing by 2030'

Miliband: 'Great British Energy will be self-financing by 2030' -

New ranking measures how Europe’s biggest retailers report on sustainability

New ranking measures how Europe’s biggest retailers report on sustainability -

Music faces a bum note without elephant dung, new research warns

Music faces a bum note without elephant dung, new research warns -

Scientists are racing to protect sea coral with robots and AI as heatwaves devastate reefs

Scientists are racing to protect sea coral with robots and AI as heatwaves devastate reefs -

Munich unveils new hydrogen lab as Europe steps up green energy race

Munich unveils new hydrogen lab as Europe steps up green energy race -

Seaweed and wind turbines: the unlikely climate double act making waves in the North Sea

Seaweed and wind turbines: the unlikely climate double act making waves in the North Sea -

Coming to a shoe spore near you: the world’s first mushroom-made trainers

Coming to a shoe spore near you: the world’s first mushroom-made trainers -

UK backs new generation of floating wind with Crown Estate leasing and £400m investment

UK backs new generation of floating wind with Crown Estate leasing and £400m investment -

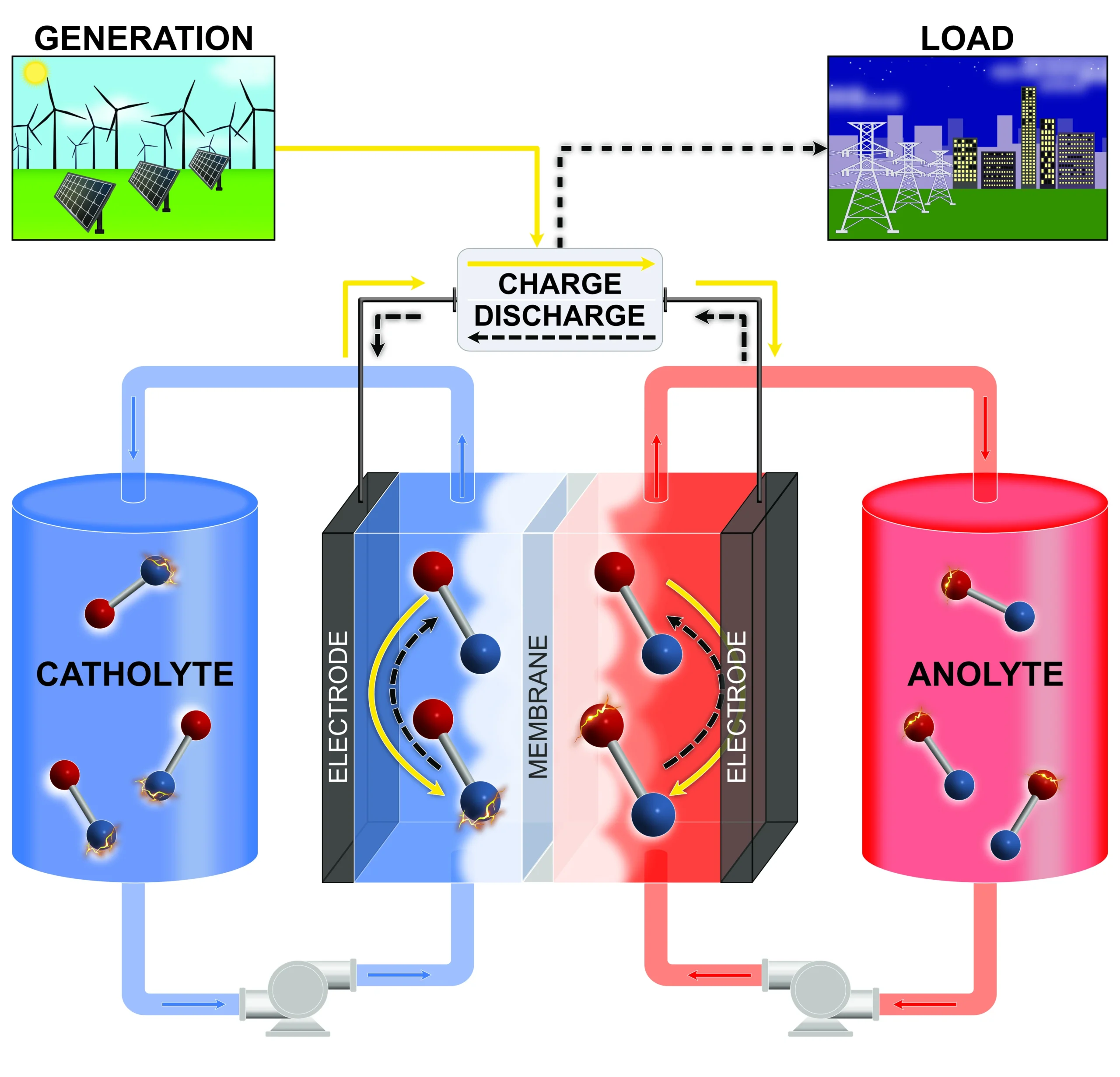

No lithium. No cobalt. No vanadium. The organic battery revolution begins

No lithium. No cobalt. No vanadium. The organic battery revolution begins -

New book tackles the hard truths behind the UN’s 17 SDGs

New book tackles the hard truths behind the UN’s 17 SDGs -

Exclusive: Breaking boundaries at the top of the world

Exclusive: Breaking boundaries at the top of the world -

ees Europe: The rise of large-scale storage systems

ees Europe: The rise of large-scale storage systems