The future of shock absorbers in autonomous and electric vehicles

John E. Kaye

- Published

- Home, Sustainability

As the automotive industry moves towards autonomous driving and electric mobility, shock absorbers, a key part of vehicle suspension systems, are undergoing transformation. Designed primarily for conventional vehicles with internal combustion engines (ICE), traditional shock absorbers must adapt to the demands of modern electric and autonomous cars. This article explores how these innovations are reshaping shock absorber technology, focusing on leading European manufacturers and their contributions.

Adapting to change in the evolution of shock absorbers

With the rise of electric vehicles (EVs) and autonomous driving systems, shock absorbers face new challenges. EVs have different weight distribution due to battery placement, affecting the vehicle’s centre of gravity. This shift necessitates recalibrating suspension systems, where shock absorbers play a crucial role.

In autonomous vehicles, dynamics differ. Since these systems aim to reduce human intervention, shock absorbers must be fine-tuned for precise and real-time adjustments. This requirement drives the development of adaptive and semi-active suspension systems that respond to varying road conditions efficiently.

Technological advancements in adaptive and active systems

A major innovation in shock absorber technology is the development of adaptive and active suspension systems. These use sensors and electronically controlled dampers to adjust settings in real-time, enhancing comfort and safety. Companies like Continental and ZF, prominent European manufacturers, lead in this area.

Continental’s predictive suspension system uses cameras and sensors to anticipate road conditions and adjust the shock absorbers. This technology ensures a smoother ride, particularly important for EVs, where a quieter cabin is a key feature. The system’s ability to adapt to terrain showcases the integration of artificial intelligence (AI) and sensor technology within modern suspension setups.

ZF has developed a semi-active suspension system that dynamically adjusts damping forces based on the vehicle’s driving mode and road conditions. This technology benefits EVs and autonomous vehicles, enhancing stability and comfort while minimising energy consumption—essential for extending electric cars’ range.

Impact of electrification and adjusting to new vehicle designs

The shift towards electric vehicles brings unique challenges for shock absorbers. Electric cars often have heavier structures due to battery packs. This weight requires shock absorbers to be more robust, capable of handling additional stress while maintaining performance. Additionally, the quieter nature of EVs means passengers are more sensitive to vibrations or noises from the suspension, necessitating refined designs.

Manufacturers now focus on lightweight materials and designs that support heavier battery packs without compromising performance. Using advanced composites and alloys, engineers create shock absorbers that provide strength while minimising weight. This balance is crucial for maintaining efficiency and range in electric vehicles.

Precision and real-time adjustment in autonomous driving

Autonomous vehicles have specific requirements for shock absorbers. These vehicles rely on precise sensor input to adjust systems, including suspension, in real-time. Shock absorbers in autonomous cars must work with the central control system, adjusting damping forces based on data from road sensors, cameras and AI algorithms.

Leading companies are integrating predictive algorithms that detect and respond to potential road irregularities before the vehicle encounters them. This not only improves passenger comfort but also enhances safety by ensuring the vehicle maintains optimal road contact.

AI and IoT integration in suspension systems for future trends

The integration of AI and the Internet of Things (IoT) is revolutionising shock absorbers. AI-enabled systems can learn and adapt to individual driving habits, personalising the suspension experience. With real-time connectivity, IoT allows shock absorbers to communicate with other vehicle systems, like braking and steering, providing a cohesive and responsive driving experience.

European manufacturers, including Bosch and Bilstein, explore AI integration for next-generation shock absorbers. These innovations aim to connect the vehicle’s sensors with its suspension system, ensuring adjustments are quick and preemptive, improving ride quality and safety.

Verified statistics and market trends

Statistics highlight the growing demand for advanced suspension systems in Europe. According to the European Automobile Manufacturers Association (ACEA), the market for adaptive and semi-active suspension systems is set to grow by 7.8 % annually over the next five years. This growth is driven by increased electric and autonomous vehicle production, with companies like AUTODOC reporting a surge in demand for compatible parts.

Conclusion

As electric and autonomous vehicles become more common, the role of shock absorbers will continue to evolve. Integrating new technologies like AI, predictive analytics and lightweight materials is reshaping how shock absorbers function, offering improved comfort, safety and efficiency. Leading European manufacturers are developing solutions that meet modern vehicle demands and set future industry standards.

The future of shock absorbers in autonomous and electric vehicles is bright, with innovation ensuring they remain critical in enhancing performance and passenger comfort. As technology advances, shock absorbers will continue shaping the driving experience of tomorrow.

RECENT ARTICLES

-

Strong ESG records help firms take R&D global, study finds

Strong ESG records help firms take R&D global, study finds -

How residence and citizenship programmes strengthen national resilience

How residence and citizenship programmes strengthen national resilience -

Global leaders enter 2026 facing a defining climate choice

Global leaders enter 2026 facing a defining climate choice -

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change -

China’s BYD overtakes Tesla as world’s largest electric car seller

China’s BYD overtakes Tesla as world’s largest electric car seller -

UK education group signs agreement to operate UN training centre network hub

UK education group signs agreement to operate UN training centre network hub -

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing -

Oxford to host new annual youth climate summit on UN World Environment Day

Oxford to host new annual youth climate summit on UN World Environment Day -

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan -

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns -

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests -

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement -

Historic motorsport confronts its energy future

Historic motorsport confronts its energy future -

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation -

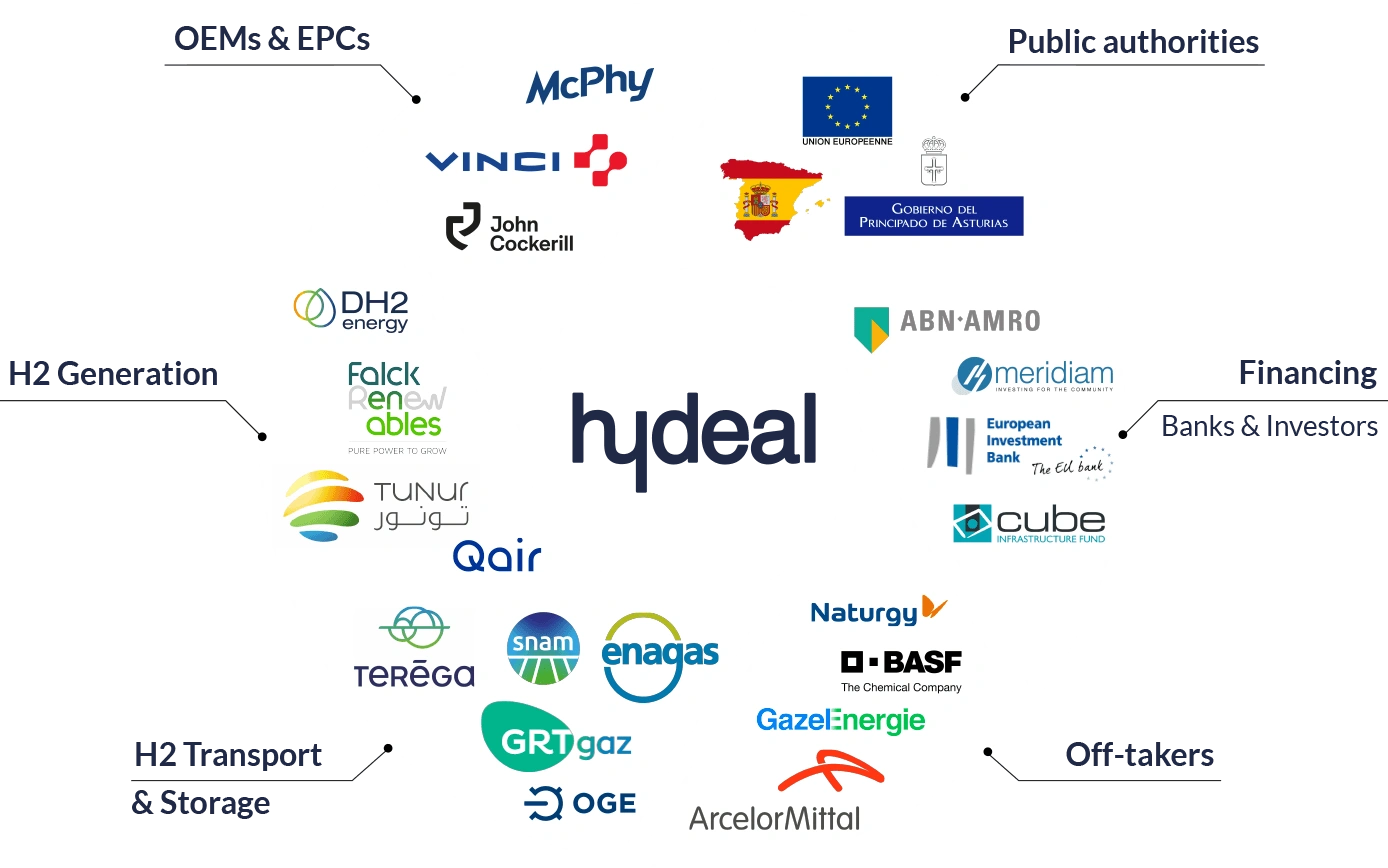

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe -

Fabric of change

Fabric of change -

Courage in an uncertain world: how fashion builds resilience now

Courage in an uncertain world: how fashion builds resilience now -

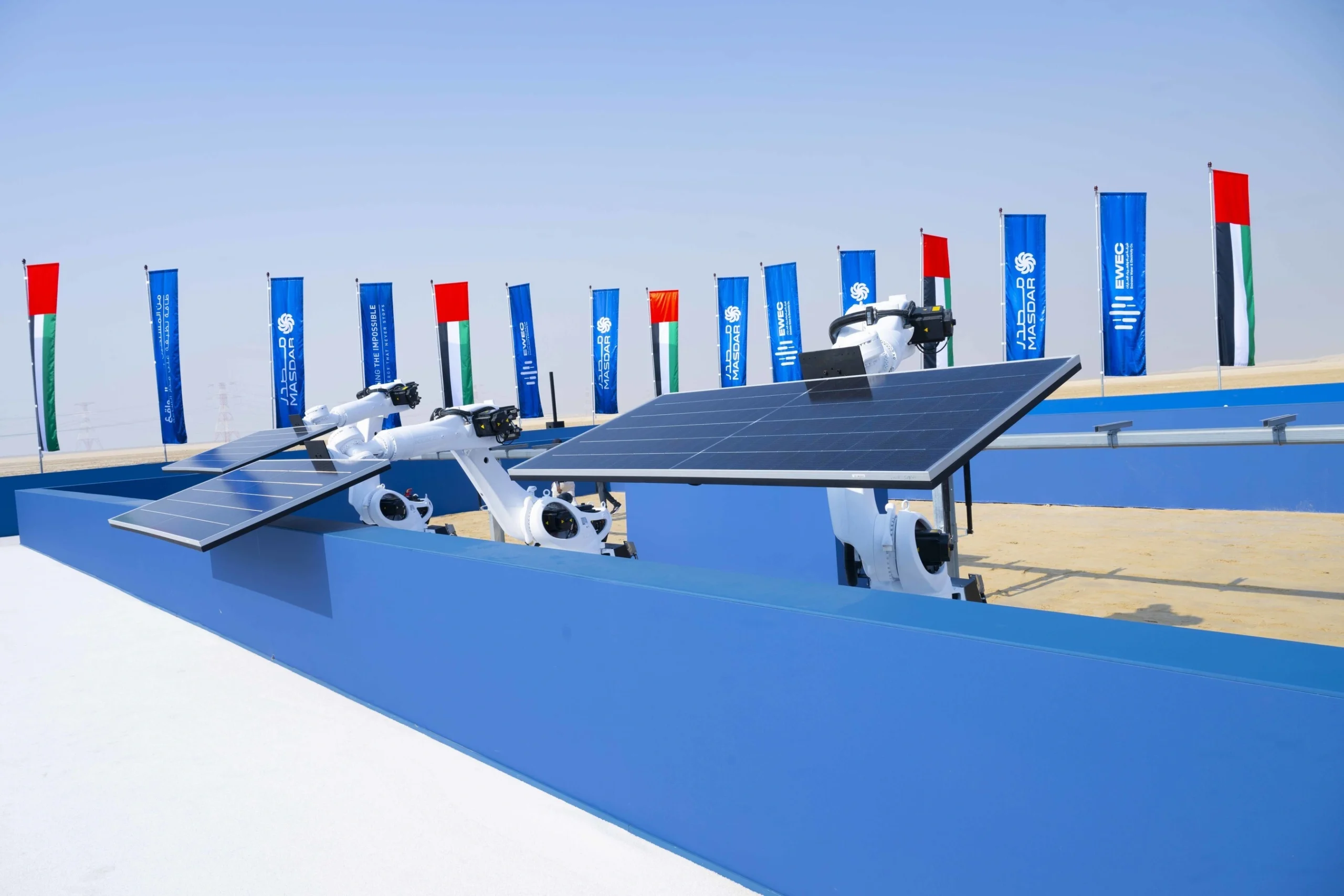

UAE breaks ground on world’s first 24-hour renewable power plant

UAE breaks ground on world’s first 24-hour renewable power plant -

China’s Yancheng sets a global benchmark for conservation and climate action

China’s Yancheng sets a global benchmark for conservation and climate action -

Inside Iceland’s green biotechnology revolution

Inside Iceland’s green biotechnology revolution -

Global development banks agree new priorities on finance, water security and private capital ahead of COP30

Global development banks agree new priorities on finance, water security and private capital ahead of COP30 -

UK organisations show rising net zero ambition despite financial pressures, new survey finds

UK organisations show rising net zero ambition despite financial pressures, new survey finds -

Gulf ESG efforts fail to link profit with sustainability, study shows

Gulf ESG efforts fail to link profit with sustainability, study shows -

Redress and UN network call for fashion industry to meet sustainability goals

Redress and UN network call for fashion industry to meet sustainability goals -

World Coastal Forum leaders warn of accelerating global ecosystem collapse

World Coastal Forum leaders warn of accelerating global ecosystem collapse