Turning the tide on plastic

John E. Kaye

- Published

- Home, Sustainability

Plastic takes up to 1,000 years to decompose, yet we are polluting the planet with it at an alarming rate. However, a team of engineers have found a way to alleviate the problem, and in doing so, convert plastic and other commercial waste into clean heat and energy.

A crisis of our making

The scale of the threat facing marine environments around the world from plastic pollution has become headline news. Thanks to programmes such as the BBC’s Blue Planet 2, the problem has entered the public consciousness in a way that is starting to change our behaviour. Public pressure and successful campaigns by environmental groups has led to certain everyday items, such as plastic straws, to be heavily curtailed and even banned. New and mind-boggling information is delivered every day as we come to recognise the scale of the problem: five trillion pieces (160 million tonnes) of plastic are reported to have already entered the world’s rivers and oceans, with eight million tonnes entering each year. Or the fact that there is a garbage patch three times the size of France floating in the Pacific, known as the “Great Pacific Garbage Patch” – with several others drifting across the oceans. We are becoming all too familiar with heart-breaking images of sea turtles tangled in plastic from a six-pack of beer, beaches resembling landfill sites or dolphins attempting to navigate their way through swamps of waste.

It begs the question of whether we are past the tipping point in the scale of plastic pollution? Furthermore, we are beginning to feel the consequences of our actions in the food chain, with microplastics discovered in all manner of marine life – terrifyingly the UN reports that plastic waste mass will surpass ocean plankton by 2050.

With the pace and scale of the problem, we are often left thinking that, despite our individual recycling efforts, plastic is out of control. And to some extent it is, so we look to governments for radical action, who in turn look to supermarkets and retailers to take the lead; progress is slow. But what if there was another solution, what if it really is possible to alleviate plastic pollution and produce clean energy in the process?

Meet Vortios

Burning waste has, up until now, not offered a viable solution. Traditional incinerators rely on coal or gas to power them, and have not been able to find a suitable temperature to prevent them from producing dioxins or other pathogens. In other words, more pollution.

But a group of intrepid engineers have decided to tackle the problem head-on by fostering a long-forgotten technology

originally conceptualised in the 1930s. Vortios is a thermal destruction technology that has the ability to incinerate plastic and other waste materials without producing any harmful by-products. What’s more, the system is able to produce six thermal MW of heat energy from one tonne of waste and can convert this into 1 MW of electricity. Enough energy to make 25,000 light bulbs glow for one hour, bake five hundred cakes or make 12,000 cups of tea. Using residual heat-energy in the system to dry waste material in preparation for the process, a fist-sized lump of residue is the only by-product from the process.

CleanOcean365

CleanOcean365’s newly designed thermal combustion system, Vortios, is self-sustaining. Once up to operating temperature it requires no fuel source, other than air and the waste it is burning, for continuous operation and power generation. The team has found that by regulating a number of vital parameters – such as temperature, airflow, feed rate, cooling and steam generation – at the correct levels, it is possible to ensure the complete and efficient destruction of waste materials.

Managing more than plastic

Whilst much of the attention is focused on plastic – which is a derivative of oil or its by-products – the CleanOcean365 thermal combustion system’s applications are wide and varied. It is also able to burn through rubber, oil, medical waste products, specialised and hazardous materials or liquids, car frag from the manufacturing process and refuse-derived fuel (RDF), and household waste. Therefore its uses range from humanitarian projects, such as cleaning the world’s oceans and rivers, through to reducing the dependency of small island nations on petrochemicals. This will enable them to be more self-sufficient from their own waste-to-power generation and create commercial opportunities in the process.

Although the technology is commercially proven, there is currently nothing comparable in the market. CleanOcean365 aims to complete its third generation Vortios system by the end of 2018, and are in active discussion with a major manufacturing entity as well as other major industrial users about orders. Not only will the manufacturer be able to safely dispose of their waste, their cost of business will dramatically reduce thanks to the Vortios waste-to-energy system.

Plans for the future

CleanOcean365 are committed to cleaning rivers, oceans and landfills in order to deliver a cleaner and greener planet for future generations.

CleanOcean365 have already attracted the attention of a number of investors who not only recognise the business potential, but are also attracted by the positive social and environmental impact the technology will have. The third-generation system will be even more efficient, more durable, transportable and more easily deployed than ever before. The system is able to fit into ISO shipping containers and requires no civil works for its deployment other than a firm, level surface. The system can be deployed on both land and sea to address the numerous and varied waste disposal challenges globally. Its small footprint means it can be deployed rapidly, and, as it is not a permanent structure, it does not require planning permission.

Furthermore, it can be mounted onto river barges and ocean-going vessels to remove the waste at source. The system’s portable nature means relocation can be done in a few days. With just a few moving parts, the durable construction means minimal maintenance. Through plastic pollution the human race has drifted into a nightmare scenario and this world-changing technology offers a profitable solution. With further investment, industry can really get down to tackling the plastic problem.

Further information

www.finov8.co.uk/cleanocean365

RECENT ARTICLES

-

Strong ESG records help firms take R&D global, study finds

Strong ESG records help firms take R&D global, study finds -

How residence and citizenship programmes strengthen national resilience

How residence and citizenship programmes strengthen national resilience -

Global leaders enter 2026 facing a defining climate choice

Global leaders enter 2026 facing a defining climate choice -

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change -

China’s BYD overtakes Tesla as world’s largest electric car seller

China’s BYD overtakes Tesla as world’s largest electric car seller -

UK education group signs agreement to operate UN training centre network hub

UK education group signs agreement to operate UN training centre network hub -

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing -

Oxford to host new annual youth climate summit on UN World Environment Day

Oxford to host new annual youth climate summit on UN World Environment Day -

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan -

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns -

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests -

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement -

Historic motorsport confronts its energy future

Historic motorsport confronts its energy future -

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation -

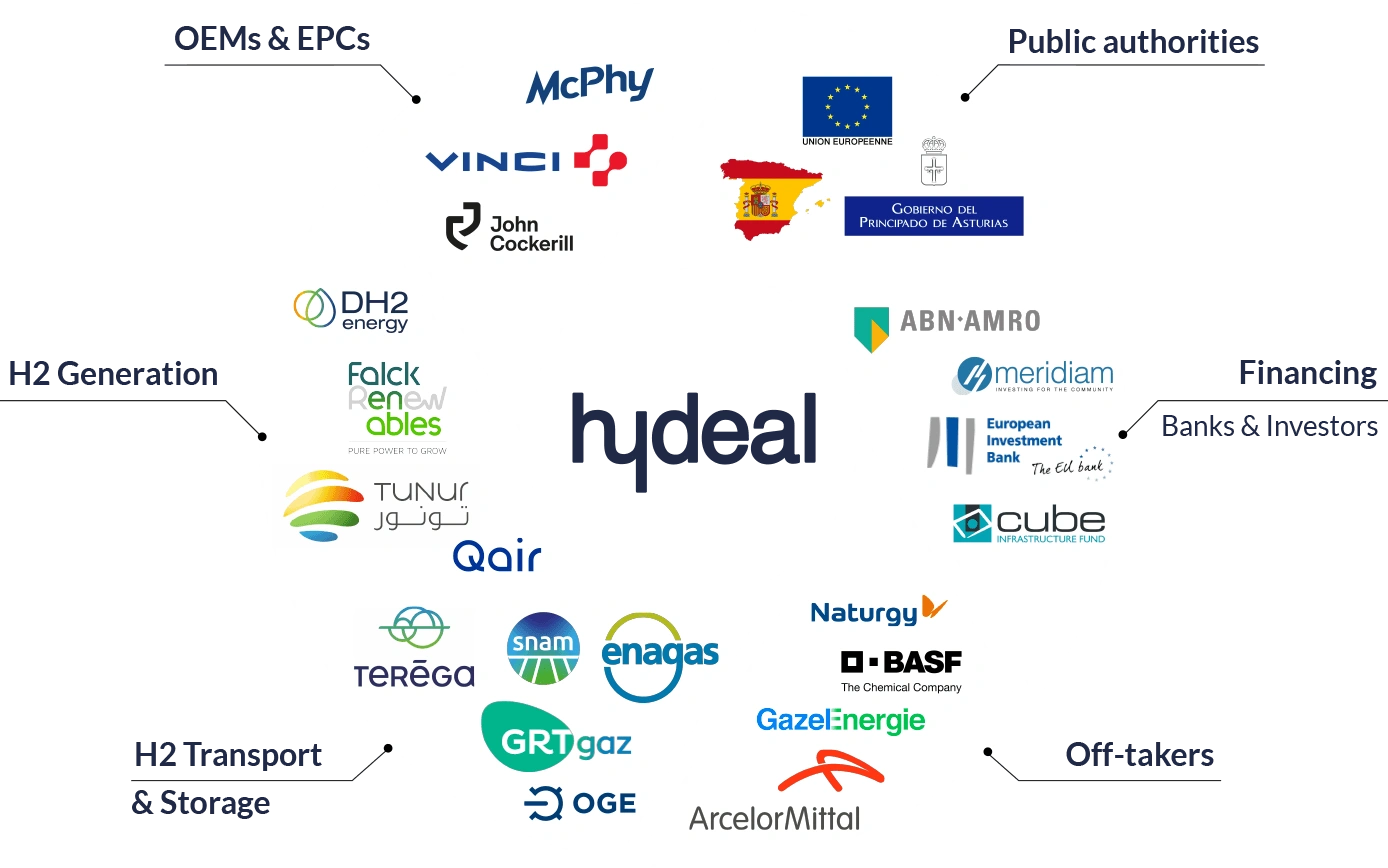

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe -

Fabric of change

Fabric of change -

Courage in an uncertain world: how fashion builds resilience now

Courage in an uncertain world: how fashion builds resilience now -

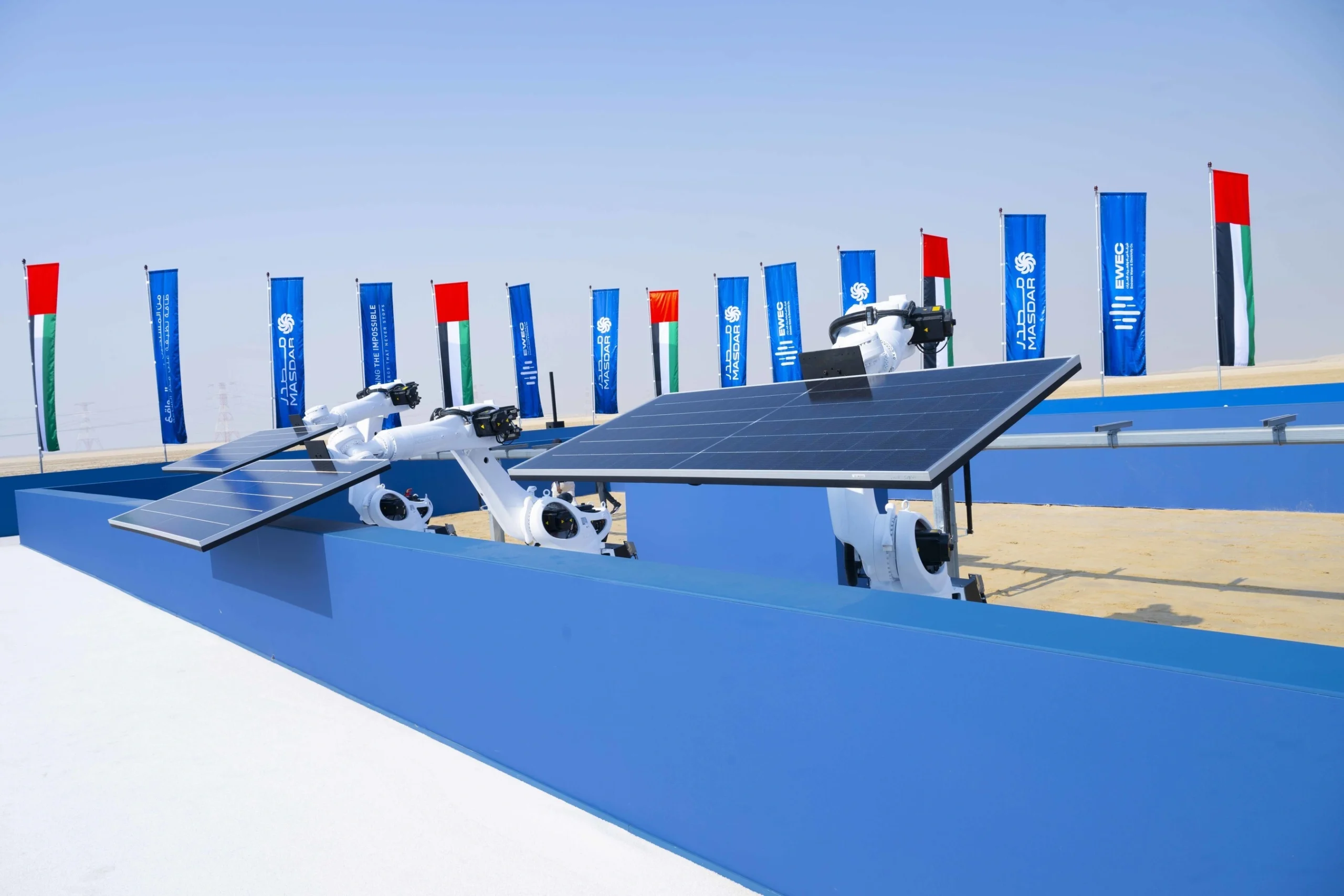

UAE breaks ground on world’s first 24-hour renewable power plant

UAE breaks ground on world’s first 24-hour renewable power plant -

China’s Yancheng sets a global benchmark for conservation and climate action

China’s Yancheng sets a global benchmark for conservation and climate action -

Inside Iceland’s green biotechnology revolution

Inside Iceland’s green biotechnology revolution -

Global development banks agree new priorities on finance, water security and private capital ahead of COP30

Global development banks agree new priorities on finance, water security and private capital ahead of COP30 -

UK organisations show rising net zero ambition despite financial pressures, new survey finds

UK organisations show rising net zero ambition despite financial pressures, new survey finds -

Gulf ESG efforts fail to link profit with sustainability, study shows

Gulf ESG efforts fail to link profit with sustainability, study shows -

Redress and UN network call for fashion industry to meet sustainability goals

Redress and UN network call for fashion industry to meet sustainability goals -

World Coastal Forum leaders warn of accelerating global ecosystem collapse

World Coastal Forum leaders warn of accelerating global ecosystem collapse