How a tiny Black Forest village became a global watchmaking powerhouse

John E. Kaye

- Published

- Business Travel, Lifestyle

From cockpits to modern collectors’ wrists, Hanhart has spent more than 140 years building precision instruments that measure life’s most critical moments. In the Black Forest village of Gütenbach, John E. Kaye meets the watchmakers, historians and engineers keeping that legacy alive through the 417 ES Heritage Flyback and the Preventor HD12 — two very different watches united by a single, uncompromising purpose

The road into Gütenbach winds between pine forests and steep hillsides, crossing streams that feed the Rhine basin before reaching a small village where, for more than 90 years, Hanhart’s workshops have shared the landscape with clockmakers, toy craftsmen and precision engineering firms. Since 1934, it has been the home of some of the most recognisable military chronographs in German aviation history.

Before the Bundeswehr contract of the 1950s, the company had already made its mark with the world’s first affordable mechanical stopwatch in 1924. “It was a breakthrough,” Simon Hall, one of Hanhart’s two CEOs, says as he walks me past a display of early timers and pilot’s watches in the on-site museum. “It brought professional timing to sport, science, and industry. From there, we moved naturally into chronographs, and those became indispensable to pilots.”

The company’s roots reach back to 1882, when Johann Adolf Hanhart opened his watch shop in Diessenhofen, Switzerland. Twenty years later, the family relocated to Schwenningen am Neckar, then the largest watchmaking town in the world. Under Wilhelm Julius Hanhart, the brand expanded into wrist and pocket watches, and by the late 1930s was producing the single-pusher Calibre 40 and the two-pusher Calibre 41, watches robust enough to serve in demanding environments, including the cockpits of German military aircraft.

By 1957, Hanhart had become the sole supplier of chronographs to the re-formed German Air Force, delivering the Calibre 42 Bundeswehr Chronograph, the direct ancestor of the modern 417 ES Heritage Flyback.

Inside the firm’s manufacturing plant today, the air smells faintly of oiled metal. Light pours in through tall windows onto rows of benches, each one set with trays of tiny gears, jewel bearings, and polished cases. Watchmakers, each wearing a magnifying loupe over one eye, lean over their benches to work on gears and springs no larger than a grain of rice. One engineer, Michael Mager, has been working here for several years. “You have to respect the materials,” he explains. “A good watch will tell you when you’re rushing. It demands patience — the same patience it will give back to the person who wears it for decades.”

It is here, alongside the museum, that Hanhart produces its mechanical stopwatches. The company manufactures more than 95% of all stopwatch components on site, from plates to gear wheels. “Producing our stopwatches in-house allows us to maintain the quality and precision that ‘Made in Germany’ demands,’ Hall explains.

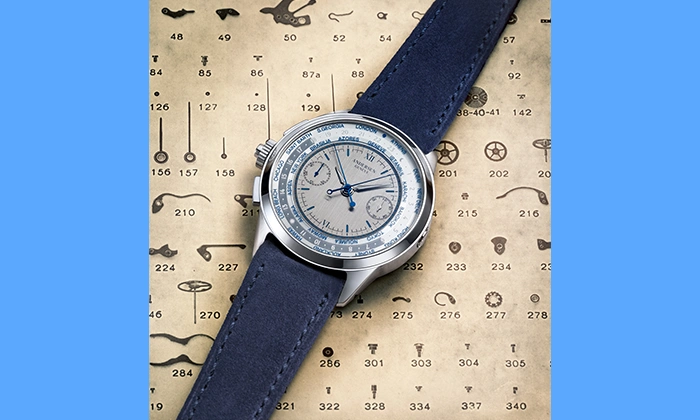

The 417 ES Heritage Flyback is the spiritual flagship of Hanhart’s current range. A direct descendant of the chronograph issued to German pilots in the 1950s, it harks back to an era when a watch was as essential as a compass or altimeter. “It was built for survival as much as for navigation,” Hall says. “Our role is to carry that history forward, but make sure it performs to modern expectations.”

Its design remains faithful to its predecessor: a black dial with symmetrical subdials, typography lifted directly from the mid-century original, and Super-LumiNova X2 C3 lume for crisp legibility without glare. The fluted bi-directional bezel, with its red timing marker, turns with a deliberate smoothness that speaks to careful machining. Most distinctive of all is the red chronograph pusher, a detail that began as a matter of survival rather than style. In the cockpit, a pilot’s chronograph was essential for calculating flight times, fuel reserves, and navigation fixes. Accidentally pressing the reset pusher mid-flight could wipe out crucial timing data. The solution was simple and effective: make the reset button stand out visually so it could not be mistaken for the start/stop control.

“There’s a story about a pilot’s partner painting it with nail polish,” Manfred Schwer, Hanhart’s in-house historian, tells me. “Whether it happened or not, the function is what mattered.” Today, the red pusher remains a hallmark of Hanhart design, but instead of paint, it’s crafted from HyCeram, a hybrid of ceramic and polymer chosen for its durability, colourfastness, and gloss — a modern upgrade to a feature born in the age of propeller-driven aircraft.

Inside is the AMT5100 M, a hand-wound movement based on Sellita’s top-tier architecture, with a column wheel for crisp pusher feel, a 58-hour power reserve, and the flyback function that resets and restarts the chronograph in a single motion. The Flyback comes in two sizes: a historically accurate 39mm, and a 42mm version with an exhibition case back. Both are fitted with domed sapphire crystals that soften the dial’s edge, recalling vintage acrylic.

Nearby, a watchmaker is inspecting the Preventor HD12, a modern three-hand watch designed for daily wear. “The 417 is our link to history,” Hall says. “The Preventor is about the present, something simple, strong, and dependable that can handle anything.”

Its case is made from proprietary HD12 steel, hardened through carbon diffusion and PVD coating to 1200 Vickers — over five times harder than standard stainless steel. At 39mm in diameter and 10.5mm in height, it wears easily under a cuff.

The matte black or dark blue dial features luminous Arabic numerals, Super-LumiNova C1-coated hands, and a slim red-tipped seconds hand as a nod to the 417’s pusher. Inside is the Soprod SOP P024, regulated to between +0 and +8 seconds per day. Straps include calfskin leather with Alcantara lining, or a steel bracelet with PVD coating.

The brand’s renewed attention from collectors reflects a broader revival of German tool watches. Sinn’s cockpit chronographs, Damasko’s ice-hardened cases, and Laco’s observation watches form part of the same landscape. These buyers value authenticity and proven performance over fashion-driven design.

In the corner of the workshop, a watchmaker closes a case back with a quiet click. “That sound,” Hall tells me, “is the last step before it leaves here. A smartwatch will be outdated in a few years. A mechanical watch, if you care for it, will be there for the next generation. That’s what we build for.”

Hanhart’s long-standing motto, Others show the time, Hanhart measures it, comes through in the deliberate pace of the workshop, the focus of its watchmakers, and the assurance that every instrument leaving Gütenbach is built to last for generations. The Hanhart Museum is open to visitors by appointment. Please register in advance by phone or email. It showcases rare pieces from the company’s history and offers the chance to watch its craftspeople at work — an experience that reflects the manufactory’s place on Germany’s Manufactory Route since 2017.

Hanhart: A Brief History

1882 – Johann Adolf Hanhart opens a watch shop in Diessenhofen, Switzerland

1902 – Relocates to Schwenningen am Neckar, then the world’s largest watchmaking town

1924 – Willy Hanhart launches the first affordable mechanical stopwatch

1934 – Opens second manufactory in Gütenbach, Black Forest

1938 – Develops single-pusher Calibre 40 chronograph; Calibre 41 follows in 1940

1953–62 – Produces the 417 ES Flyback and other pilot’s chronographs for the Bundeswehr; sole supplier to the German armed forces

1960s–70s – Expands stopwatch production, becoming Europe’s market leader

1970s–80s – Counters quartz crisis by producing its own plastic injection moulding and quartz calibre 3305

Late 1990s – Revives legendary pilot’s chronographs as new editions

2000s–present – Reissues and modern interpretations join new tool-watch lines, including the 417 ES Heritage Flyback and Preventor HD12™

Main image: The entrance to Hanhart’s manufactory in Gütenbach showcases the brand’s legacy in motorsport, aviation, and maritime timing, underscoring its reputation as a leader in German watchmaking since 1882. Photo: Hanhart

RECENT ARTICLES

-

Need some downtime? Head to Nerja for some serious decompression

Need some downtime? Head to Nerja for some serious decompression -

How a book becomes a ‘bestseller (and it’s not what you think)

How a book becomes a ‘bestseller (and it’s not what you think) -

Fipronil: the silent killer in our waterways

Fipronil: the silent killer in our waterways -

Addiction remains misunderstood despite clear medical consensus

Addiction remains misunderstood despite clear medical consensus -

New guide to the NC500 calls time on 'tick-box tourism'

New guide to the NC500 calls time on 'tick-box tourism' -

Bon anniversaire, Rétromobile: Paris’ great motor show turns 50

Bon anniversaire, Rétromobile: Paris’ great motor show turns 50 -

Ski hard, rest harder: inside Europe’s new winter-wellness boom

Ski hard, rest harder: inside Europe’s new winter-wellness boom -

Baden-Baden: Europe’s capital of the art of living

Baden-Baden: Europe’s capital of the art of living -

Salzburg in 2026: celebrating 270 years of Mozart’s genius

Salzburg in 2026: celebrating 270 years of Mozart’s genius -

Sea Princess Nika – the ultimate expression of Adriatic elegance on Lošinj

Sea Princess Nika – the ultimate expression of Adriatic elegance on Lošinj -

Hotel Bellevue, Lošinj, Croatia – refined wellness by the Adriatic

Hotel Bellevue, Lošinj, Croatia – refined wellness by the Adriatic -

Padstow beyond Stein is a food lover’s dream

Padstow beyond Stein is a food lover’s dream -

Love really is in the air. How to spot a sky full of heart-stealing stars this Valentine's Day

Love really is in the air. How to spot a sky full of heart-stealing stars this Valentine's Day -

Cora Cora Maldives – freedom, luxury and a celebration of island life

Cora Cora Maldives – freedom, luxury and a celebration of island life -

Hotel Ambasador: the place to stay in Split

Hotel Ambasador: the place to stay in Split -

Maslina Resort, Hvar – mindful luxury in the heart of the Adriatic

Maslina Resort, Hvar – mindful luxury in the heart of the Adriatic -

The bon hiver guide to Paris

The bon hiver guide to Paris -

Villa Mirasol – timeless luxury and discreet elegance on the island of Lošinj

Villa Mirasol – timeless luxury and discreet elegance on the island of Lošinj -

Lošinj’s Captain’s Villa Rouge sets a new standard in private luxury hospitality

Lošinj’s Captain’s Villa Rouge sets a new standard in private luxury hospitality -

Villa Nai 3.3: A Michelin-recognised haven on Dugi Otok

Villa Nai 3.3: A Michelin-recognised haven on Dugi Otok -

The European road test: The Jeep Wrangler Rubicon

The European road test: The Jeep Wrangler Rubicon -

Rattrapante Mondiale – Split-Seconds Worldtimer

Rattrapante Mondiale – Split-Seconds Worldtimer -

Adaaran Select Meedhupparu & Prestige Water Villas: a Raa Atoll retreat

Adaaran Select Meedhupparu & Prestige Water Villas: a Raa Atoll retreat -

Heritance Aarah: an island escape crafted for exceptional family and couples’ stays

Heritance Aarah: an island escape crafted for exceptional family and couples’ stays -

Stanley Johnson in Botswana: a return to the wild heart of Southern Africa

Stanley Johnson in Botswana: a return to the wild heart of Southern Africa