Quitting her career in the leather industry to pioneer a sustainable, award-winning alternative was never going to be easy, but that didn’t stop Carmen Hijosa, as Tania Braukamper discovers

Dr Carmen Hijosa believes there’s hope for the planet. Although her particular breed of optimism is subdued, it is also infectious; indeed, conversing with her is an exercise in bolstered spirits and reinforced beliefs in the power of solutions-based thinking.

What’s more, her words have the weight of her accomplishments behind them: Dr Hijosa is the founder of Ananas Anam Ltd, and the award-winning inventor of Piñatex, the much-talked-about alternative to leather made from pineapple leaf waste.

It took Dr Hijosa 10 years to develop Piñatex. To make it happen, she went back to study at the Royal College of Art in London. She gained a Ph.D in Textiles aged 62 years old, and to fund her research, she won multiple scholarships and even re-mortgaged her house. Quitting was never an option.

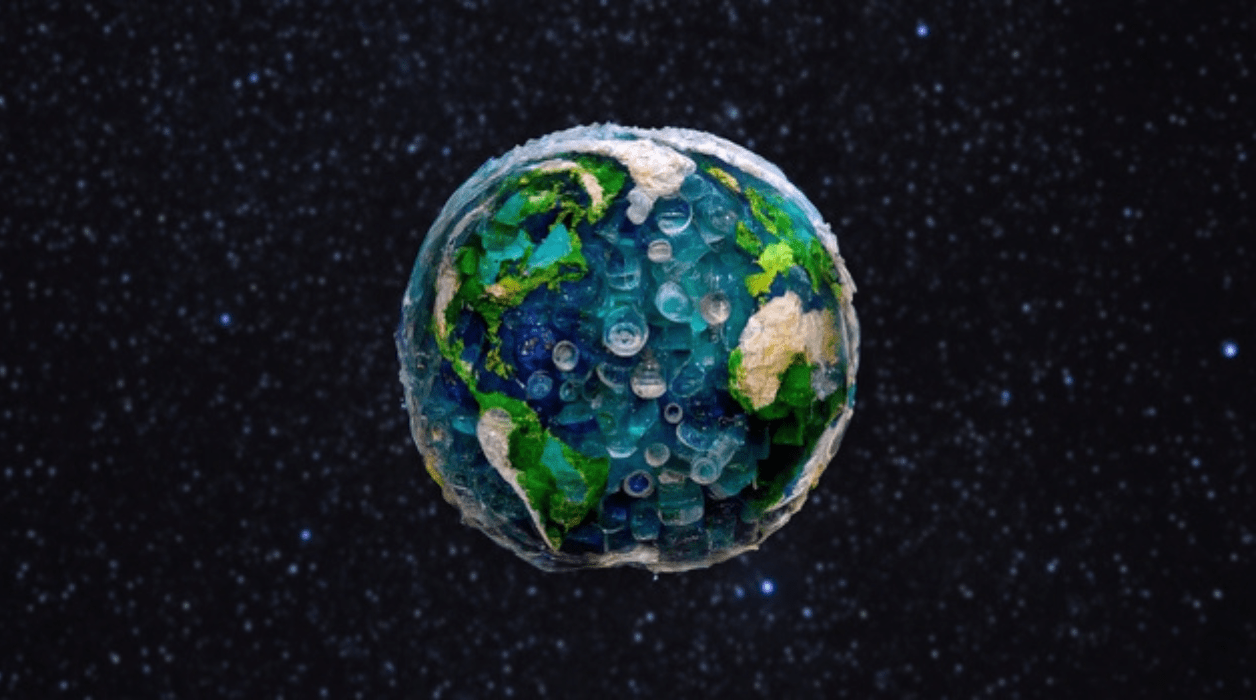

The drive to create a more sustainable alternative to leather came from seeing the devastating impact of tanneries first-hand. As Dr Hijosa tells it, she first got her experience with leather from running a successful company designing, manufacturing and selling leather fashion accessories. Later, while working as a consultant, she visited leather tanneries in the Philippines. She was shocked by the conditions; the excess wastewater, the alarming glut of toxic chemicals. “That shook me to my core,” she says. “And basically, I thought, that’s the end of my business – which it was.”

New beginnings

One door closed, but it wasn’t as simple as just waiting for another to open. The door she wanted didn’t exist yet – she had to knock a hole in the wall of the leather industry to create it. That new door was Piñatex. At the time it launched in 2015, it was the first plantbased leather alternative on the market.

The sustainability credentials of Piñatex are manifold. Firstly, there’s the low environmental impact. “When you think of using waste from agriculture, that is already a huge difference – not having to use any extra land, any water, pesticides, or fertilisers,” explains Dr Hijosa.

Then there’s the transparency of the supply chain, “because there was no supply chain before, we had to build it ourselves.” It’s upscalable. And, it takes into account what Dr. Hijosa calls the three pillars of society: social, ecological, and economic. For Ananas Anam, that means paying people the right amount and nurturing farming communities in some of the most underdeveloped parts of the world. “We’re giving employment, they’ve got security, everything is legal… and that costs whatever it costs, but that is absolutely critical.”

Going mainstream

In the beginning, Piñatex was taken up by niche vegan brands. Now, it’s breaking through to the mainstream. You can get Nike sneakers made from Piñatex. You can find it in the collections of Zara and H&M. It even clads the bespoke furniture in the world’s first vegan hotel suite at the Hilton London Bankside.

“We went from small to medium vegan companies to big companies, and that really gave us the push to upscaling our production,” says Dr Hijosa. “If big companies want to do something a bit more sustainable, we can make sure that our product helps.”

Last year, Ananas Anam launched another lowimpact, pineapple-based material into the market called Piñayarn – a compostable and biodegradable yarn made with zero harmful chemicals and a zerowaste production cycle. And Dr Hijosa believes the possibilities for pineapple waste are far from exhausted. “It’s non-stop. My head is bubbling with ideas.”

A world of possibilities

The potential of pineapple leaf fibre is so vast thanks to its unique combination of properties: it’s fine, strong, and flexible. On top of that, there’s the abundance of by-product just waiting to be picked up, dusted off, and repurposed into something beautiful. Accordingto Dr Hijosa: “There’s the waste. 27 million tonnes of [pineapple leaf] waste in the world, and hypothetically, if we use all that we could make enough Piñatex to go around the world three times. And that’s a wonderful thing to think – three times around the world and we’re not using one single pineapple, we don’t have to plant one seed.”

She compares this with the Amazon – where 80% of deforestation is done by cattle ranching – to illustrate the bigger picture of how important these fibres are to her and to the future of the industry. Replacing animal leathers with materials made from agricultural waste can, and will, make a measurable difference on multiple levels.

More work to be done

Despite the success of Ananas Anam’s products to date, all efforts toward sustainability require a process of constant evolution and optimisation. “There is always more work to be done,” says Dr Hijosa.

In 2021, the company reduced its water usage by around 73%, and they are working to similarly minimise energy use. She admits that nothing is perfect and everything we do has an impact. “We still need to balance, because we work now from Spain, from the Philippines; our fibres come also from the Ivory Coast and Bangladesh, so you cannot expect everyone to be at the same level in a lifecycle analysis.

“We will reach carbon neutral at some point, our lifecycle is nearly there but then there are other things, like travel. Flying has the most drastic impact and we still have to fly to the Philippines because that’s where we work. So, what we have to do is tackle it through better systems, better collaborations, better machines.”

The value of humble fibres

Crucially, the unwavering commitment that took Piñatex from the seed of an idea to the flourishing plant of an ethical business remains strong. Dr Hijosa credits her resilience to an inner drive to do what she feels is right.

“I feel so strongly about working with natural fibres that come from agricultural waste, and to really bring about value for these very humble fibres… It’s ethics and economics as one, this is what we say in my company.

“At the end of the day,” she continues, “you have to think with the heart. Not just with the head, which can be extremely materialistic. And that doesn’t mean that the heart is a very soft, soapy thing whatsoever – it’s actually a very honest and upright, a moral and ethical thing, because that is when it all comes about.”

She adds that the mission she founded the company on has not changed: “Every textile we create and every fibre we regenerate, we fight for a better planet,” she says. “I still get emotional thinking, this is what it is, it’s fighting for a better planet. Also, it’s the vision – the vision is to heal the rift between people and planet, because if you don’t have this respect for nature you do not have this inner responsibility and drive.”

With this vision and drive, Dr Hijosa believes, anyone can do what she has done. It’s about looking around us with curiosity. It’s thinking, “with this I can make this, and what can I do with this?”

“To use our imagination is critical because sometimes we’re so much in our computers… But it’s just a matter of being out there and being in awe at the miracle of the colours and the flowers from a seed to a plant. I mean, if we can bring this to our young generations, I think we have a chance. There is always hope.”

She laughs and opens her hands in a gesture that suggests point made, case closed, no space for doubts. “To me,” she says “that’s it!”

ABOUT THE AUTHOR

Tania Braukamper is a freelance writer specialising in fashion and lifestyle.