Inside Iceland’s green biotechnology revolution

John E. Kaye

- Published

- Sustainability

From a geothermal facility on Iceland’s Reykjanes Peninsula, Algalíf has built Europe’s most advanced microalgae plant — and in doing so, has turned sustainability from a corporate claim into a measurable discipline, finds John E. Kaye

On the vast lava fields of Reykjanes, where geothermal steam rises from the earth in rhythmic clouds and powers entire communities, Iceland has found an unexpected export: biotechnology. From this alien, volcanic landscape, Algalíf has become Europe’s largest producer of Haematococcus pluvialis, the red microalga behind astaxanthin, a natural antioxidant now used by nutraceutical and skincare brands worldwide. Its story is a study in how science and sustainability, properly aligned, can transform production itself.

“Over the years we’ve learned that success is built on constant innovation,” Orri Björnsson, its CEO, told The European. “We’re not just producing astaxanthin but developing new ways to do so far cleaner, smarter, and more sustainably than anyone else.”

Astaxanthin, the compound that gives salmon and flamingos their distinctive hue, is among nature’s most powerful antioxidants. It has been the subject of more than a hundred human clinical trials and thousands of peer-reviewed papers exploring its effects on oxidative balance, cardiovascular and muscle recovery, skin vitality, and healthy ageing. Algalíf’s distinction, Björnsson tells me, lies in the purity of its extract and in the integrity of its production.

Everything is cultivated and processed in a closed-loop facility powered entirely by geothermal energy and supplied with pure, unchlorinated water naturally filtered through volcanic rock. From cultivation to extraction, the operation is carbon-neutral — in practice, carbon-negative — with zero fossil fuels, zero waste, and a minimal environmental footprint. Each stage of production follows cGMP standards and is monitored by automated systems supported by an in-house team of scientists and engineers.

At the core of this system is the company’s 13,500-square-metre plant, the largest of its kind in Europe. Within it, Algalíf uses closed photobioreactors equipped with proprietary LED lighting that replicates the precise wavelength and intensity required for optimal microalgae growth. The controlled environment eliminates contamination risk and ensures exceptional yield consistency, with astaxanthin concentrations reaching up to seven per cent in dried biomass — among the highest recorded globally.

Algalíf’s analytical laboratory performs full product characterisation, ensuring that each batch meets the same standards of safety, purity and potency. The company’s digital infrastructure adds a further layer of precision; every process is sensor-driven and data-verified, allowing real-time monitoring of temperature, light, nutrient balance and flow rates. It means each metric is traceable from raw input to finished product, creating a transparent supply chain that customers can audit at any time.

“Our systems are designed to learn, adapt and improve,” Björnsson explained. “Innovation starts with data, and data drives progress.”

This philosophy has produced one of the most notable technical advances in natural antioxidants in recent years. In 2025, Algalíf launched Astalíf™ 15, a global first: a natural astaxanthin oleoresin containing a consistent 15 per cent concentration. Developed entirely in Iceland and powered exclusively by renewable energy, it marks a breakthrough in both efficiency and stability. The formulation allows nutraceutical companies to create smaller, more potent capsules and functional products with reduced material use and lower transport impact.

“Creating Astalíf™ 15 demanded years of scientific dedication and continuous process optimisation,” Björnsson said. “It’s a perfect example of what Icelandic innovation can achieve — combining biotechnology, sustainability and precision engineering to reach new frontiers.”

Behind that frontier is a strong research culture. Algalíf collaborates with universities and research centres across Europe and North America to advance algae science, photobioreactor technology and sustainable bioengineering. The company invests heavily in process modelling, nutrient profiling and solvent-free CO₂ extraction techniques that improve yield and consistency without compromising purity. Each development feeds back into the production line, strengthening both the science and the sustainability of the operation.

From its base in Iceland, Algalíf now exports to major markets across Europe, Asia, North America and Australia. Its logistics network, supported by specialist distributors, ensures reliable supply to nutraceutical, cosmetic and pet-nutrition brands worldwide. Many of the industry’s most recognisable names source their astaxanthin directly from the company, drawn by its proven consistency and environmental credentials. “Reliability is essential,” Björnsson explained. “Our partners expect the highest standards — and we deliver them consistently, batch after batch.”

Astaxanthin’s protective potential is well established. Its molecular structure allows it to span cell membranes and shield both the inner and outer layers from oxidative damage, a property that makes it up to 6,000 times stronger than vitamin C, 800 times more potent than CoQ10, and 500 times more active than vitamin E in neutralising free radicals. Studies suggest it supports cardiovascular wellness, muscle endurance, recovery, and skin elasticity by reducing UV-induced inflammation.

Algalíf’s advantage lies in its combination of efficacy and transparency. Its astaxanthin is cultivated under strictly controlled conditions and extracted using supercritical CO₂, with no chemical residues or solvents. Independent testing verifies purity and bioavailability. “Consumers today want ingredients that truly work and also come from transparent, sustainable, and ethical sources. That’s where Algalíf makes a difference.”

The company’s environmental ethos aligns closely with Iceland’s broader energy policy. Iceland is powered almost entirely by renewable resources, and Algalíf reflects that national commitment in corporate form. In addition to its cGMP certification, the company undergoes regular third-party audits and is recognised internationally for carbon-neutral operations and its zero-waste, zero-fossil-fuel policy. “Our responsibility goes beyond business performance,” Björnsson told me. “We’re part of a global movement toward cleaner, more transparent production.”

As demand for natural and science-backed ingredients continues to rise, Algalíf is investing further in research collaborations that extend algae’s potential into new fields, from functional foods and cosmetics to sustainable natural pigments. Its approach, Björnsson said, demonstrates how biotechnology can expand responsibly, combining industrial precision with ecological restraint.

“From this remote peninsula on the edge of the North Atlantic, Algalíf has shown how a company grounded in scientific discipline can also embody environmental conscience. In doing so, it has turned Iceland’s geothermal landscape into a proving ground for the future of green biotechnology.”

Further information

Produced with support from Algalíf Iceland. To find out more about its sustainable astaxanthin ingredients and biotechnology innovations, visit www.algalif.com

RECENT ARTICLES

-

Strong ESG records help firms take R&D global, study finds

Strong ESG records help firms take R&D global, study finds -

How residence and citizenship programmes strengthen national resilience

How residence and citizenship programmes strengthen national resilience -

Global leaders enter 2026 facing a defining climate choice

Global leaders enter 2026 facing a defining climate choice -

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change -

China’s BYD overtakes Tesla as world’s largest electric car seller

China’s BYD overtakes Tesla as world’s largest electric car seller -

UK education group signs agreement to operate UN training centre network hub

UK education group signs agreement to operate UN training centre network hub -

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing -

Oxford to host new annual youth climate summit on UN World Environment Day

Oxford to host new annual youth climate summit on UN World Environment Day -

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan -

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns -

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests -

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement -

Historic motorsport confronts its energy future

Historic motorsport confronts its energy future -

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation -

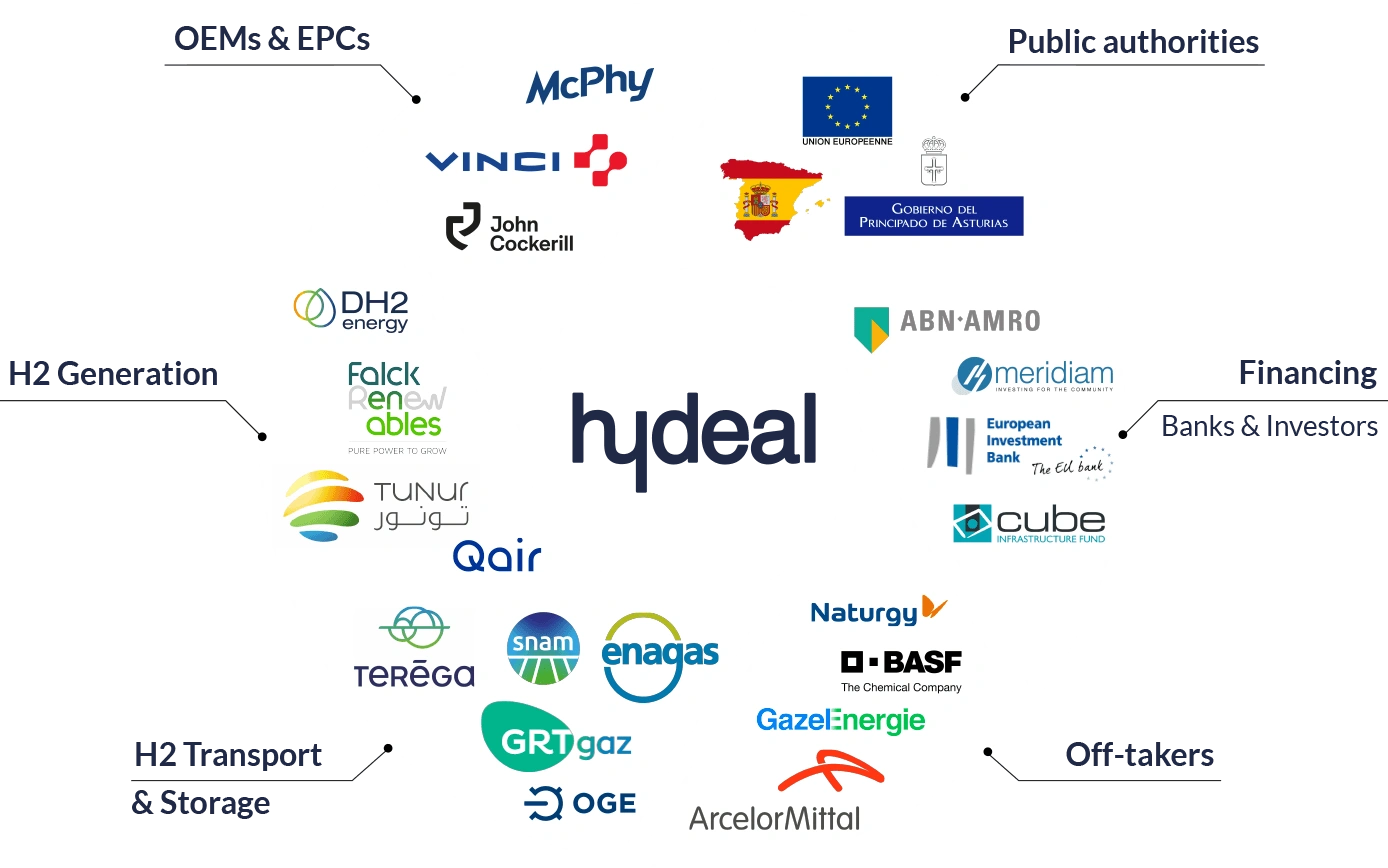

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe -

Fabric of change

Fabric of change -

Courage in an uncertain world: how fashion builds resilience now

Courage in an uncertain world: how fashion builds resilience now -

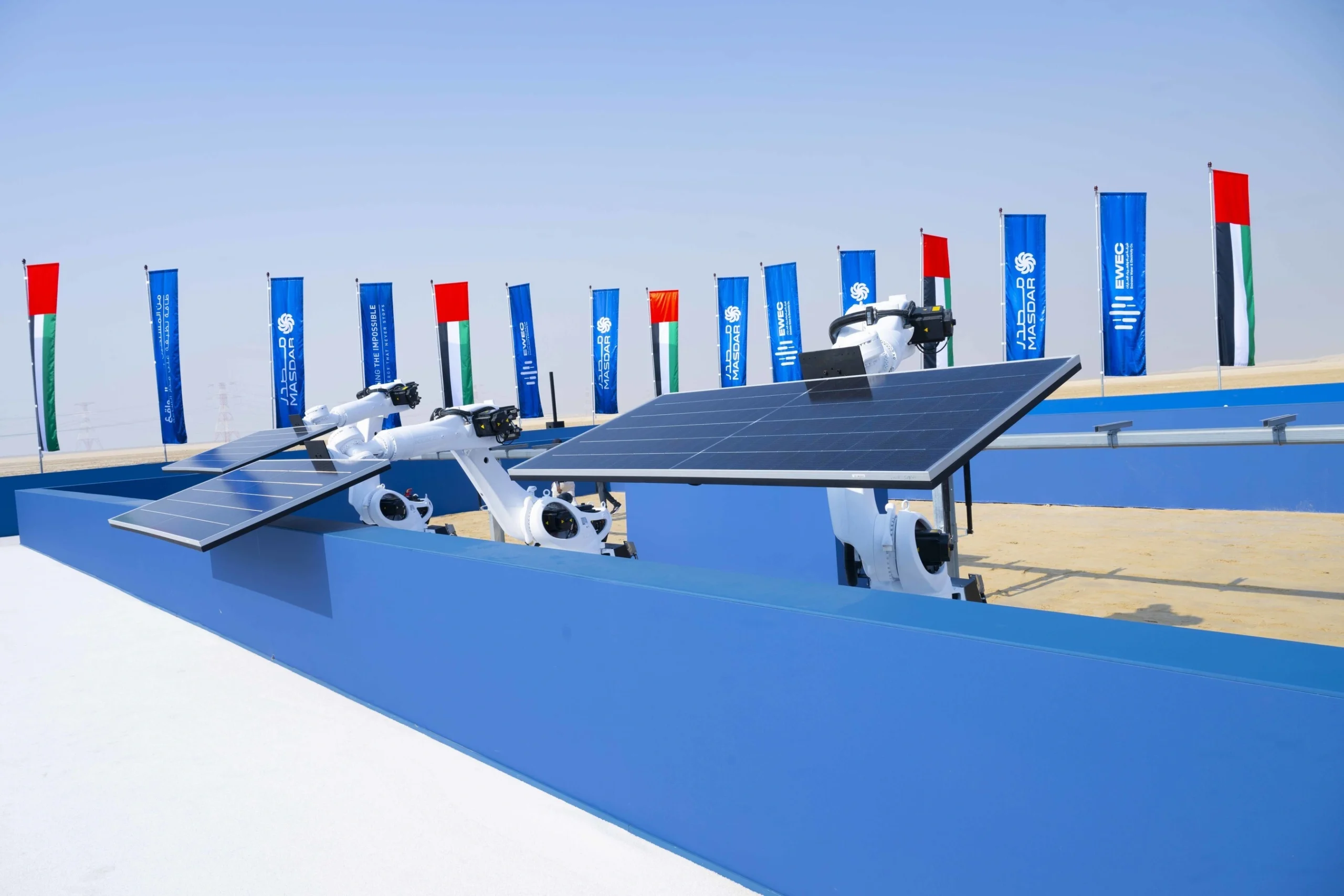

UAE breaks ground on world’s first 24-hour renewable power plant

UAE breaks ground on world’s first 24-hour renewable power plant -

China’s Yancheng sets a global benchmark for conservation and climate action

China’s Yancheng sets a global benchmark for conservation and climate action -

Inside Iceland’s green biotechnology revolution

Inside Iceland’s green biotechnology revolution -

Global development banks agree new priorities on finance, water security and private capital ahead of COP30

Global development banks agree new priorities on finance, water security and private capital ahead of COP30 -

UK organisations show rising net zero ambition despite financial pressures, new survey finds

UK organisations show rising net zero ambition despite financial pressures, new survey finds -

Gulf ESG efforts fail to link profit with sustainability, study shows

Gulf ESG efforts fail to link profit with sustainability, study shows -

Redress and UN network call for fashion industry to meet sustainability goals

Redress and UN network call for fashion industry to meet sustainability goals -

World Coastal Forum leaders warn of accelerating global ecosystem collapse

World Coastal Forum leaders warn of accelerating global ecosystem collapse