Navigating the Red Sea supply chain crisis

John E. Kaye

- Published

- Banking & Finance, Global Economy, Home

The situation in the Red Sea presents an opportunity for organisations to reevaluate their operational models, embrace digital transformation and adopt emerging technologies, says Stuart Swindell of Dun & Bradstreet

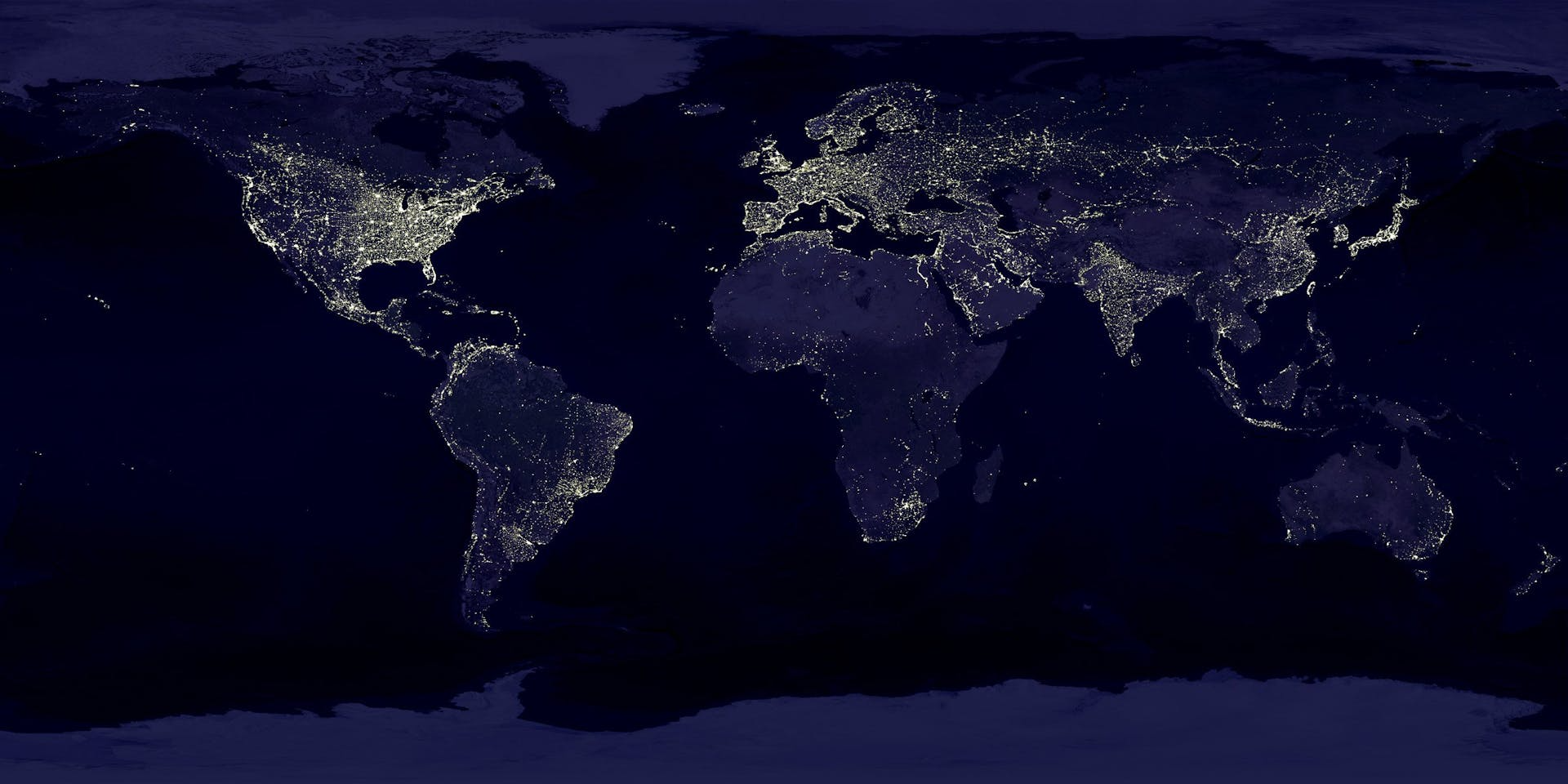

In an era marked by global interconnectedness, supply chains serve as the lifeblood of economies worldwide. But in recent weeks, global supply chains have encountered troubled waters, with the conflict surrounding the Red Sea leading to delays, bottlenecks, price inflation, and shortages of goods worldwide. Bordered by six sovereign nations, with five actively engaged in shipping – Egypt, Eritrea, Israel, Sudan, and Yemen – the Red Sea serves as a vital shipping route, connecting one end of the Suez Canal.

However, the current blockade is impacting businesses seriously, with Dun & Bradstreet’s latest shipping insights data revealing that there has been a 21% decrease in shipping container imports to Europe through shipping routes passing through the Red Sea since December 2023. The ongoing disruption in the Red Sea is contributing to constrained supplies in Europe. What’s more the British Chambers of Commerce revealed that the on-going disruption in the Red Sea has impacted more than a third of UK firms.

Troubled waters

As disruptions continue to unfold, businesses are grappling with unprecedented challenges that underscore the critical importance of resilient supply chain management. From shipping delays and increased insurance costs to heightened security risks, businesses operating in and around the Red Sea are facing unprecedented challenges that demand swift and strategic action.

At the heart of this crisis lies several factors, including geopolitical tensions and logistical bottlenecks. The recent blockade of key maritime routes has exacerbated existing vulnerabilities, disrupting the flow of goods and amplifying supply chain complexities. Container ships being diverted on much longer routes around the Red Sea are costing businesses more money, causing delays and leading to inflated prices for consumers.

This disruption is also reflected in Dun & Bradstreet’s latest Global Supply Chain Continuity Index, which fell sharply by 6% for Q1 2024 compared with Q4 2023, with suppliers’ delivery time and delivery cost indices both deteriorating. With many retailers maintaining a just-in-time supply chain, they are especially vulnerable to these sorts of crises, which can lead to pricing inflation and vulnerability to external shocks. These shocks can exacerbate existing economic challenges, for instance the UK economy is already experiencing a recession, and this crisis is set to further impact the stability and business resilience of the market.

Bridging the supply chain gap

For businesses operating in this dynamic landscape, adaptability is paramount. Companies are facing the herculean task of making their supply chains more resilient and sustainable as a way of securing better protection from unanticipated events such as climate change or conflict. And this can only be achieved by leveraging data and analytics – either utilising a business’s own first party data or partnering with a third party to provide further visibility. By doing this, organisations will be better positioned to understand the evolving risk landscape, enabling proactive decision-making and smarter decisions which can ultimately lead to a more resilient supply chain.

Real-time monitoring and predictive analytics enable organisations to forecast potential disruptions based on historical trends, market dynamics, weather patterns, and geopolitical developments – empowering them to anticipate potential disruptions and implement pre-emptive measures to safeguard their operations against unforeseen events.

Central to this is supply chain visibility. By mapping dependencies and identifying alternative routes, businesses can diversify their sourcing strategies and reduce vulnerability to disruptions in the Red Sea region. Businesses also need to adopt foresight scenario planning and adapt their strategies on the basis of an evolving situation by drawing up contingency plans for a variety of supply chain disruption scenarios.

In the face of adversity, innovation thrives. The current situation in the Red Sea has underscored how interconnected our world truly is – highlighting both the opportunities and challenges inherent in today’s globalised economy. It is a stark reminder of the overlap in vulnerabilities of global supply chains. The crisis presents an opportunity for organisations to reevaluate their operational models, embrace the power of data and digital transformation, and adopt emerging technologies such as AI to enhance efficiency, transparency, and resilience. By staying informed, proactive, and collaborative, organisations can not only overcome immediate challenges but can also fortify their supply chains against future shocks to emerge stronger and more resilient in the face of future disruptions.

About the author

Stuart Swindell is Risk and Compliance Strategy Director at Dun & Bradstreet.

RECENT ARTICLES

-

Managing cross-border risks in B2B e-commerce

Managing cross-border risks in B2B e-commerce -

J.P. Morgan launches first tokenised money market fund on public blockchain

J.P. Morgan launches first tokenised money market fund on public blockchain -

Aberdeen agrees to take over management of £1.5bn in closed-end funds from MFS

Aberdeen agrees to take over management of £1.5bn in closed-end funds from MFS -

Enterprise asset management market forecast to more than double by 2035

Enterprise asset management market forecast to more than double by 2035 -

EU Chamber records highest number of entries for 2025 China Sustainable Business Awards

EU Chamber records highest number of entries for 2025 China Sustainable Business Awards -

Inside Liechtenstein’s strategy for a tighter, more demanding financial era

Inside Liechtenstein’s strategy for a tighter, more demanding financial era -

‘Stability, scale and strategy’: Christoph Reich on Liechtenstein’s evolving financial centre

‘Stability, scale and strategy’: Christoph Reich on Liechtenstein’s evolving financial centre -

Bridging tradition and transformation: Brigitte Haas on leading Liechtenstein into a new era

Bridging tradition and transformation: Brigitte Haas on leading Liechtenstein into a new era -

Liechtenstein in the Spotlight

Liechtenstein in the Spotlight -

Fiduciary responsibility in the balance between stability and global dynamics

Fiduciary responsibility in the balance between stability and global dynamics -

Neue Bank’s CEO on stability, discipline and long-term private banking

Neue Bank’s CEO on stability, discipline and long-term private banking -

Research highlights rise of 'solopreneurs' as technology reshapes small business ownership

Research highlights rise of 'solopreneurs' as technology reshapes small business ownership -

Philipp Kieber on legacy, leadership and continuity at Interadvice Anstalt

Philipp Kieber on legacy, leadership and continuity at Interadvice Anstalt -

Building global-ready funds: how South African managers are scaling through offshore platforms

Building global-ready funds: how South African managers are scaling through offshore platforms -

Global billionaire wealth hits record as relocation and inheritance accelerate, UBS finds

Global billionaire wealth hits record as relocation and inheritance accelerate, UBS finds -

Human resources at the centre of organisational transformation

Human resources at the centre of organisational transformation -

Liechtenstein lands AAA rating again as PM hails “exceptional stability”

Liechtenstein lands AAA rating again as PM hails “exceptional stability” -

Lusaka Securities Exchange surges ahead on reform momentum

Lusaka Securities Exchange surges ahead on reform momentum -

PROMEA leads with ESG, technology and trust in a changing Swiss market

PROMEA leads with ESG, technology and trust in a changing Swiss market -

Why collective action matters for pensions and the planet

Why collective action matters for pensions and the planet -

Structuring success with Moore Stephens Jersey

Structuring success with Moore Stephens Jersey -

PIM Capital sets new standards in cross-jurisdiction fund solutions

PIM Capital sets new standards in cross-jurisdiction fund solutions -

Innovation, advisory and growth: Banchile Inversiones in 2024

Innovation, advisory and growth: Banchile Inversiones in 2024 -

Digitalization, financial inclusion, and a new era of banking services: Uzbekistan’s road to WTO membership

Digitalization, financial inclusion, and a new era of banking services: Uzbekistan’s road to WTO membership -

Fermi America secures $350m in financing led by Macquarie Group

Fermi America secures $350m in financing led by Macquarie Group