A cutting-edge approach to business

John E. Kaye

An interview with Sean Robinson, CEO of STIGA Group

Renowned gardening equipment business STIGA Group have gone from strength to strength over the last two decades. 2021 was a year of record growth with sales rising 9% above the European market average. The group closed 2021 with revenues of €573m, an increase of 28% compared with €448m in 2020, significantly higher than the European market average growth of around 19%. EBITDA grew significantly, up by 39% compared with 2020.

Over the last two years, the sector has seen a significant shift in consumer behaviour, with a greater focus on the home and garden, a trend that is expected to continue. Some consumers have purchased gardening equipment for the first time, while others have decided to invest in high-performance products, which help them to maximise the enjoyment of their outside space. STIGA’s growth in 2021, 9% above the market average, shows that compared with its key competitors, the company not only increased volumes sold to existing customers but also gained important market share.

Orchestrating this growth is Sean Robinson, who was appointed CEO of STIGA in 2019. Over this period Robinson has delivered a long-term business strategy to lead the group through the gardening market’s evolutionary changes while managing growth and presence in 84 nations worldwide, with 16 own subsidiaries in Europe. The European caught up with him to learn how it has all unfolded.

The European: Tell us how your career path led you to becoming CEO of STIGA?

Sean Robinson: I started training at British Aerospace in 1981, which later became BAE Systems – a UK leader in modern technologies applied to defence and space systems. Here I gained my Bachelor of Engineering degree, a Master in Business Administration and became a Chartered Engineer. After an initial period at BAE Systems, and another at Case (a leader in construction equipment), I moved to Bosch where I held a director position between 1998 and 2002. I then joined Dyson, one of the fastest developing companies in the home appliance business, where I started as Manufacturing Director for UK and Malaysia, and was eventually appointed Managing Director of global operations, which included R&D in 2007. In 2010 I joined HYVA – a major international player in transportation/hydraulic solutions – as Chief Operating Officer based in Hong Kong, in charge of group strategy, operations, supply chain, service, product development, quality management.

In 2015 I joined Fischer & Paykel Appliances, an international player in modern home appliances and part of the global Haier Group, where I was based at the New Zealand HQ. There I was the CEO of the Technology Group and on the leadership team of the appliance group, responsible for driving the growth and development of the businesses with brilliant success in Asia, Europe and North America.

This vast experience has led me to become qualified to lead STIGA and in 2019, I joined the STIGA Group as the Group Chief Executive Officer. Adding value to the company through people, product and market innovations.

TE: What has been your overarching strategy at STIGA so far?

SR: My business strategy has been to lead the group through the gardening market’s evolutionary changes while managing growth and presence in 84 nations worldwide, with 16 own subsidiaries in Europe. I have established a five-year strategic plan, restructured and strengthened the organisation, and increased investments in R&D and branding while reinforcing the company’s culture and results’ orientation. The cornerstones of this strategy have been the introduction of new battery-powered products, such as the exceptional autonomous robots which will be launched this year, and entering into new categories, such as the handheld segment and Axial mowers, whilst at the same time consolidating the company’s leadership role in its core segment, namely products for mowing the lawn.

TE: We understand that you feel very strongly about sustainability?

SR: I am very passionate about sustainability and a strong supporter of sustainable methods across industry, and believe that the STIGA Group – as a leading innovator and with 100 years of experience in the garden products sector – is committed to influencing the garden equipment sector. Using more sustainable power sources, materials, recyclability and, as a design leader, helping consumers create, nurture and enjoy their own little piece of nature with resource-smart solutions.

In 2020 we pledged to accelerate the pace of the group’s sustainable practices and we are planning even more ambitious goals in the coming years, raising the bar for STIGA and the industry. In 2021, STIGA started its sustainability journey by drafting its first internal Sustainability Report. This year, STIGA has decided to expand the perimeter to the whole group by publishing the report, so that all stakeholders can be aware of the actions that have been taken to deliver on our commitment to the future.

The analysis of our data revealed that important progress is already being made, and that we began our journey towards 360-degree sustainability at the right time.

STIGA allocated specific internal and external resources to the project with the objective of developing the right level of awareness, in addition to adequate processes and organisation inside the company. STIGA wants to establish a more sustainable business aligned with the expectations of its stakeholders, affirming its commitment to sustainability with a focus on environmental and social objectives.

At STIGA we are green-fingered engineers. We care about our gardeners and their gardens, and we are committed to design and manufacture products with a lower environmental impact. We are committed to creating products that are electricity powered, made with recycled materials, high quality standards, and are connected, robust and long-lasting. As an example, we encourage the use of mulching because this means less fertilisers and pesticides, less watering, and no grass disposal.

TE: We also know that innovation is central to the STIGA brand. Expand on this for us.

SR: Our business is undergoing significant change that might even be seen as revolutionary. The gardening market has always been relatively stable, with limited technological innovation. However, in the last three years there has been a gradual and irrevocable move even for large garden machines away from petrol engines to battery-powered machines. This reflects a fundamental change in both product technology and in how products are used by consumers. People want considerably less noise, less weight, no smell and for products to be made from the right materials, in other words new machines that are more sustainable. The positive results posted by our group – the increase in our market share thanks to the introduction of new technologies – show that this has been the right approach to adopt, and our prospects are bright for the future.

An example of one of our newest innovations is that of the range of the STIGA autonomous mowers. How the robot navigates inside that virtual perimeter, how it is able to take care of lawn’s health and how it makes your life much easier is what makes a STIGA autonomous robot mower completely different from all others. The robot actively maps the garden to decide where andmwhen to cut using predictive, patented AGS (Active Guidance System) technology, and when combined with RTK-GPS (multiple satellite connection) technology this ensures up to a 2cm accuracy and a strong, stable signal. All cutting zones on the lawn, no matter how big (up to 5,000sqm) are mown regularly and accurately, leaving no zone uncut, whilst also ensuring there is no over-mowing (cutting the same area several times) resulting in a beautiful even-cut lawn – you can even have stripes!

It is the first of a new breed of robot lawnmowers and combines 100 years of STIGA’s engineering innovation and expertise with a deep understanding of the science of grass. This robot has been designed and developed in Italy, at the STIGA Group headquarters and production facility in Castelfranco Veneto, Italy. This high-tech hub of innovation is home to a talented multicultural R&D department with a range of backgrounds and skills – mechanical and electronic engineers, technicians, software experts, prototype and test engineers and an agronomist.

TE: What are your interests outside of work?

SR: I love history and I always have one or two books on the go! In my free time, besides gardening, my wife Jill and I are fond of walking through the Dolomites and we are both keen tennis and paddle players.

Further information

www.stiga.com/uk

RECENT ARTICLES

-

Managing cross-border risks in B2B e-commerce

Managing cross-border risks in B2B e-commerce -

Research highlights rise of 'solopreneurs' as technology reshapes small business ownership

Research highlights rise of 'solopreneurs' as technology reshapes small business ownership -

Human resources at the centre of organisational transformation

Human resources at the centre of organisational transformation -

UK government sets up Women in Tech taskforce amid gender imbalance concerns

UK government sets up Women in Tech taskforce amid gender imbalance concerns -

Liechtenstein lands AAA rating again as PM hails “exceptional stability”

Liechtenstein lands AAA rating again as PM hails “exceptional stability” -

The Parisian business school quietly reinventing the MBA

The Parisian business school quietly reinventing the MBA -

UK entrepreneur who founded £1bn firm acquires UAE amateur golf leader to launch world amateur Super League

UK entrepreneur who founded £1bn firm acquires UAE amateur golf leader to launch world amateur Super League -

Why your home is the best place to teach children leadership

Why your home is the best place to teach children leadership -

Inside the Spring 2025 Edition of The European

Inside the Spring 2025 Edition of The European -

The Paris MBA designed for real-world leadership

The Paris MBA designed for real-world leadership -

Soft2Bet reflects on eight years of leadership and philanthropy in new film featuring CEO Uri Poliavich

Soft2Bet reflects on eight years of leadership and philanthropy in new film featuring CEO Uri Poliavich -

Global Banking School celebrates ‘milestone’ anniversary

Global Banking School celebrates ‘milestone’ anniversary -

Saudi Arabia hosts the fourth Riyadh International Humanitarian Forum

Saudi Arabia hosts the fourth Riyadh International Humanitarian Forum -

New York Congresswoman pushes for Trump’s birthday to be enshrined as federal holiday

New York Congresswoman pushes for Trump’s birthday to be enshrined as federal holiday -

Red light, green bite: Netflix restaurant opens in Vegas

Red light, green bite: Netflix restaurant opens in Vegas -

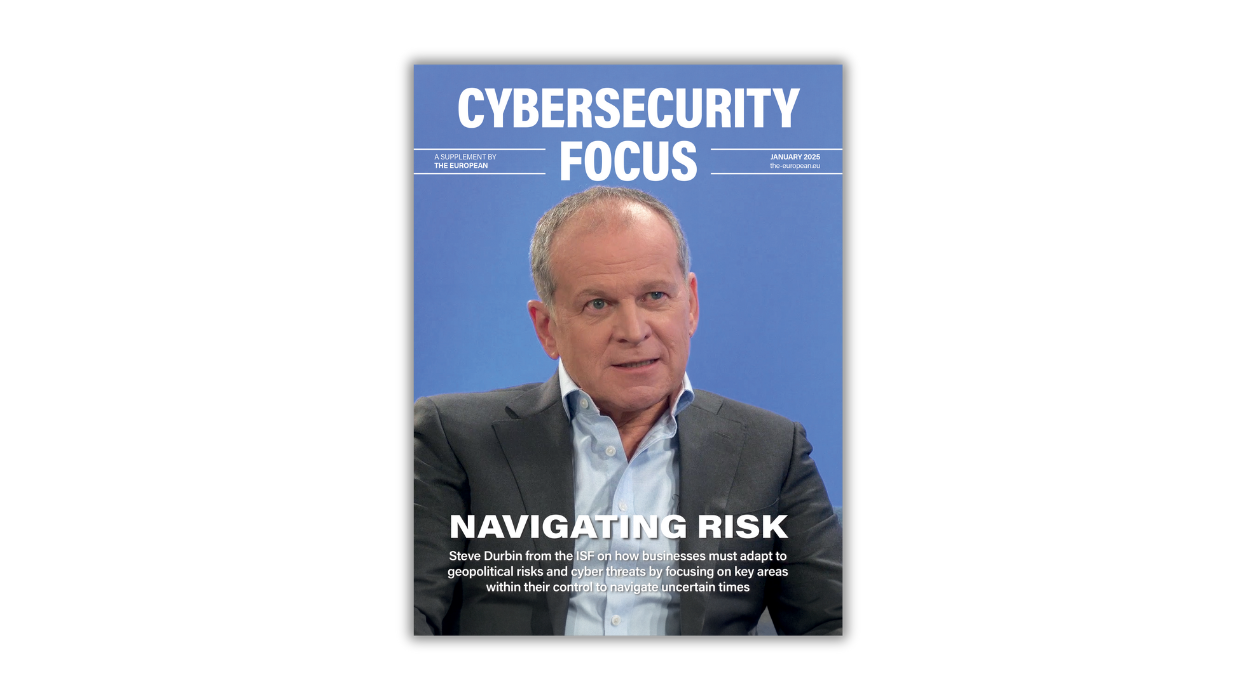

Read our Cybersecurity Focus supplement, featuring insights from Information Security Forum

Read our Cybersecurity Focus supplement, featuring insights from Information Security Forum -

Davos World Economic Forum 2025: Collaboration for the Intelligent Age

Davos World Economic Forum 2025: Collaboration for the Intelligent Age -

The European releases its Winter 2024/25 edition

The European releases its Winter 2024/25 edition -

Read our FDI Focus supplement, featuring insights from Michael Lohan of IDA Ireland

Read our FDI Focus supplement, featuring insights from Michael Lohan of IDA Ireland -

PizzaExpress to Expand Dough Base Stateside

PizzaExpress to Expand Dough Base Stateside -

The two core skills middle managers need to navigate stormy weather

The two core skills middle managers need to navigate stormy weather -

The Role of Financial Regulations in the Online Casino Industry

The Role of Financial Regulations in the Online Casino Industry -

How to become a game-changer

How to become a game-changer -

Taking the risk out of BOP ventures

Taking the risk out of BOP ventures -

Releaf leading the way with marketing

Releaf leading the way with marketing