Iberdrola and H2 Green Steel plan mega green hydrogen plant

John E. Kaye

- Published

- Home, Sustainability

Global wind power group Iberdrola and Swedish startup H2 Green Steel plan to build a vast renewable hydrogen plant on the Iberian peninsula to power the production of iron used to make steel with drastically reduced carbon emissions.

The EU is pushing the development of a supply chain for “green” hydrogen – made by splitting water molecules with renewable electricity – to replace the millions of tonnes of “grey” hydrogen – made with coal or natural gas – that its industry consumes every year.

Iberdrola and H2 Green Steel recently said they are seeking a location in Spain or Portugal to build an electrolysis plant and a direct reduction tower to treat iron ore which they hope to fire up by 2026. The planned facility’s 1 gigawatt (GW) of electrolysis capacity would far outstrip the roughly 0.3 GW currently in operation globally. The EU targets 40 GW by 2030.

Iberdrola will spend around €800m on new renewable capacity to power the electrolyser, its head of hydrogen Millan Garcia-Tolla told Reuters.

Overall the project will cost around 2.3bn euros. The companies will seek to tap equity, green project finance and public funding sources including the European Union’s €750bn pandemic recovery budget. They could later add a specific steel facility, taking as a blueprint a similar plant H2 Green Steel is planning in northern Sweden.

Producing steel with green hydrogen emits 95% less carbon than with coal, and customers are willing to pay 25% more for it, H2 Green Steel Chief Executive Henrik Henriksson said. Iberdrola wants to use green hydrogen for processes where electricity can’t be easily used.

“If first of all we attack […] those current uses of grey hydrogen and we plan projects to 2025-2026 like cement or green steel, I think we are going to make big steps,” Iberdrola’s Garcia-Tolla said.

Some question the efficiency of using green hydrogen because it will require vast amounts of clean energy production and future cost reductions are uncertain. Environmental campaigners fear work on developing it will prolong use of the polluting “grey” version. But Henriksson argued industry should work to tackle climate change with available technology. “You can always wait until tomorrow for the silver bullet but then we will wait forever,” he said.

RECENT ARTICLES

-

Strong ESG records help firms take R&D global, study finds

Strong ESG records help firms take R&D global, study finds -

How residence and citizenship programmes strengthen national resilience

How residence and citizenship programmes strengthen national resilience -

Global leaders enter 2026 facing a defining climate choice

Global leaders enter 2026 facing a defining climate choice -

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change

EU sustainability rules drive digital compliance push in Uzbekistan ahead of export change -

China’s BYD overtakes Tesla as world’s largest electric car seller

China’s BYD overtakes Tesla as world’s largest electric car seller -

UK education group signs agreement to operate UN training centre network hub

UK education group signs agreement to operate UN training centre network hub -

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing

Mycelium breakthrough shows there’s mush-room to grow in greener manufacturing -

Oxford to host new annual youth climate summit on UN World Environment Day

Oxford to host new annual youth climate summit on UN World Environment Day -

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan

Exclusive: Global United Nations delegates meet in London as GEDU sets out new cross-network sustainability plan -

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns

Fast fashion brands ‘greenwash’ shoppers with guilt-easing claims, study warns -

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests

Private sector set to overtake government as main driver of corporate sustainability in 2026, report suggests -

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement

Sir Trevor McDonald honoured at UWI London Benefit Dinner celebrating Caribbean achievement -

Historic motorsport confronts its energy future

Historic motorsport confronts its energy future -

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation

Protecting the world’s wild places: Dr Catherine Barnard on how local partnerships drive global conservation -

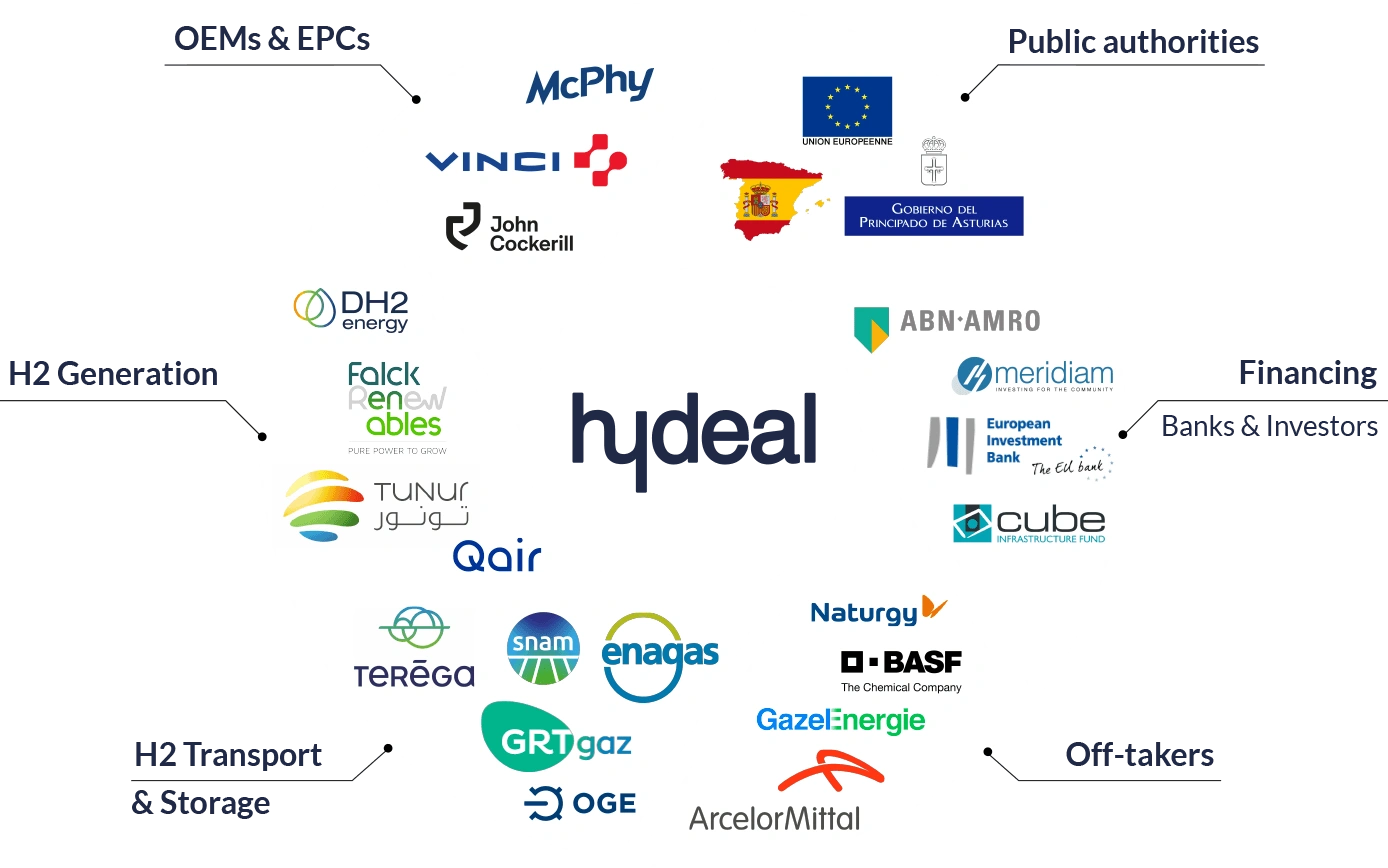

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe

Europe’s HyDeal eyes Africa for low-cost hydrogen link to Europe -

Fabric of change

Fabric of change -

Courage in an uncertain world: how fashion builds resilience now

Courage in an uncertain world: how fashion builds resilience now -

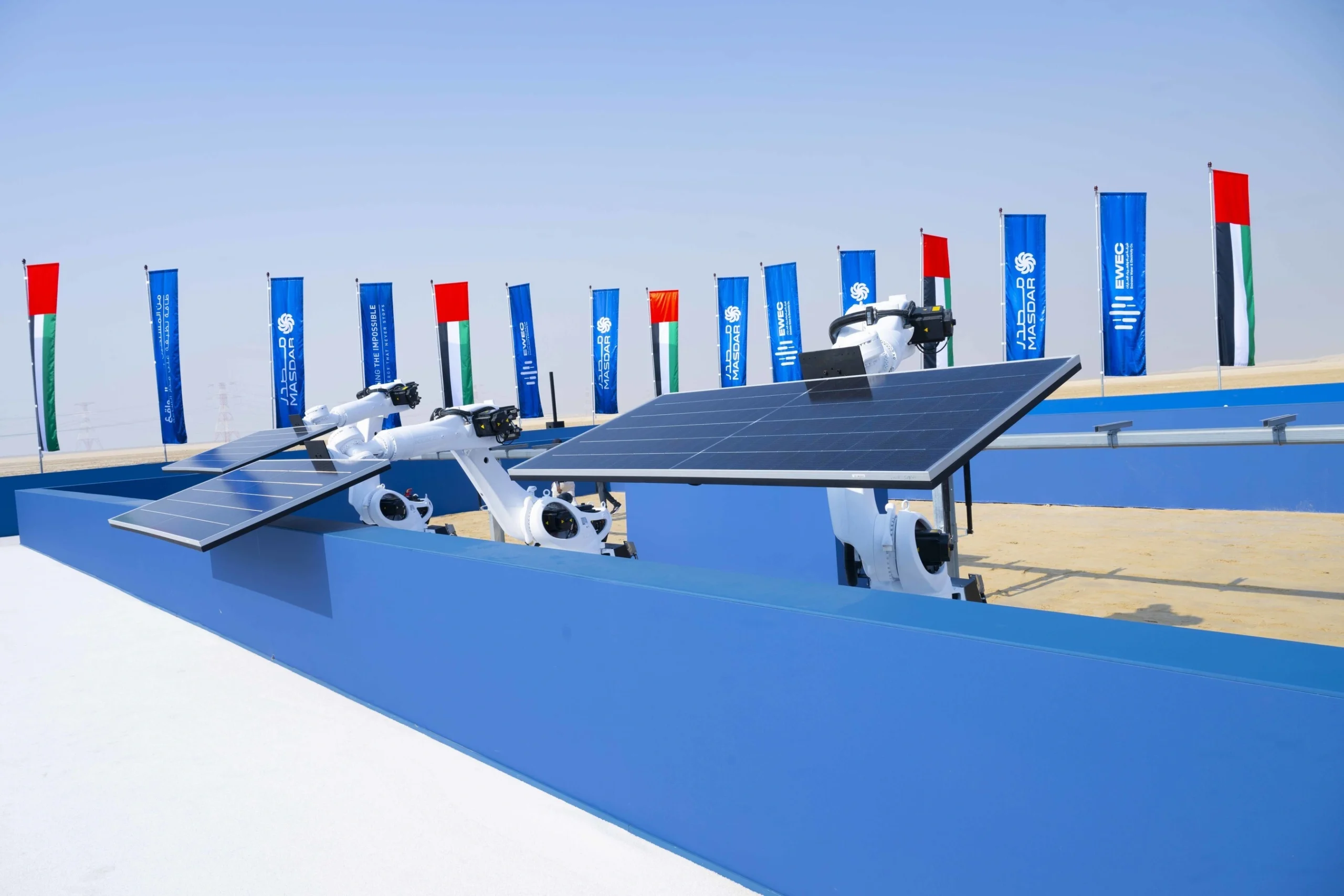

UAE breaks ground on world’s first 24-hour renewable power plant

UAE breaks ground on world’s first 24-hour renewable power plant -

China’s Yancheng sets a global benchmark for conservation and climate action

China’s Yancheng sets a global benchmark for conservation and climate action -

Inside Iceland’s green biotechnology revolution

Inside Iceland’s green biotechnology revolution -

Global development banks agree new priorities on finance, water security and private capital ahead of COP30

Global development banks agree new priorities on finance, water security and private capital ahead of COP30 -

UK organisations show rising net zero ambition despite financial pressures, new survey finds

UK organisations show rising net zero ambition despite financial pressures, new survey finds -

Gulf ESG efforts fail to link profit with sustainability, study shows

Gulf ESG efforts fail to link profit with sustainability, study shows -

Redress and UN network call for fashion industry to meet sustainability goals

Redress and UN network call for fashion industry to meet sustainability goals -

World Coastal Forum leaders warn of accelerating global ecosystem collapse

World Coastal Forum leaders warn of accelerating global ecosystem collapse